PRODUCT FEATURES

Lowrider Hydraulic Pumps Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide To Lowrider Hydraulic Pumps

Are you interested in getting Lowrider Hydraulic Pumps for your business? And with so many different types of pumps on the market, it can be tough to know which one is right for you.

With this guide, we’ll walk you through the basics of hydraulics, how it works, and the benefits of using lowrider pumps so that you can make an informed decision on which pump is right for your business. We will also provide tips on how to choose the right lowrider hydraulic pump for your needs.

Read on to learn more!

Table of contents

1. Lowrider Hydraulic Pumps: The Basics

Lowrider hydraulic pumps are a vital component of any lowrider car, and they work by using hydraulics to raise and lower a car’s suspension. The most important part of a lowrider hydraulic pump is the pump itself, which is usually located in the engine bay. The pump is connected to the car’s suspension via a series of hoses, and it uses hydraulic fluid to pressurize the system.

2. How Do Lowrider Hydraulic Pumps Work?

Lowrider hydraulic pump works by using 2 cylinders that are connected to each other. The first cylinder is filled with hydraulic fluid and the second one is empty. When the lowrider car moves, the fluid from the first cylinder flows into the second cylinder and pushes the pistons up. This action creates pressure that allows the car to move up and down.

3. Common Uses of Lowrider Hydraulic Pumps

Lowrider hydraulic pumps can be used for a variety of applications such as the following:

| Suspension Systems | Lowrider hydraulic pumps are commonly used in suspension systems, and they work by pressurizing the hydraulic fluid to raise or lower the car. The pressure of the fluid can be adjusted to create different effects, such as bouncing or lifting one side of the car. |

| Braking Systems | Hydraulic pumps can also be used in braking systems, and they work by pressurizing the hydraulic fluid to create friction. This helps to slow down or stop the vehicle. |

| Transmission Systems | Hydraulic pumps can also be used in transmission systems, and they work by pressurizing the hydraulic fluid to move the gears. This helps to change the speed of the vehicle. |

| Power Steering | Hydraulic pumps can also be used in power steering systems, and they work by pressurizing the hydraulic fluid to help turn the wheels. |

Suspension Systems

Lowrider hydraulic pumps are commonly used in suspension systems, and they work by pressurizing the hydraulic fluid to raise or lower the car. The pressure of the fluid can be adjusted to create different effects, such as bouncing or lifting one side of the car.

Braking Systems

Hydraulic pumps can also be used in braking systems, and they work by pressurizing the hydraulic fluid to create friction. This helps to slow down or stop the vehicle.

Transmission Systems

Hydraulic pumps can also be used in transmission systems, and they work by pressurizing the hydraulic fluid to move the gears. This helps to change the speed of the vehicle.

Power Steering

Hydraulic pumps can also be used in power steering systems, and they work by pressurizing the hydraulic fluid to help turn the wheels.

Overall, lowrider hydraulic pumps are a versatile and powerful type of fluid power pump that can be used for a variety of applications.

4. The Benefits of Lowrider Hydraulic Pumps

Lowrider hydraulic pumps offer a number of advantages over conventional hydraulic pumps. Here are some of the benefits of using lowrider hydraulic pumps:

Compact Size

One of the main advantages of lowrider hydraulic pumps is that they are much smaller in size than conventional hydraulic pumps. This makes them ideal for use in cars, trucks, and other vehicles where space is limited.

Lesser Noise

Another advantage of lowrider hydraulic pumps is that they tend to generate less noise than conventional hydraulic pumps. This makes them ideal for use in areas where noise levels need to be kept to a minimum.

Increased Efficiency

Lowrider hydraulic pumps are also more efficient than conventional hydraulic pumps. This means that they can generate more pressure with less fluid, which can lead to reduced operating costs.

Higher Pressures

Lowrider hydraulic pumps are also able to generate higher pressures than conventional hydraulic pumps. This makes them ideal for use in applications where high pressure is required, such as in suspension systems.

Smoother Operation

Lowrider hydraulic pumps also tend to have a smoother operation than conventional hydraulic pumps. This is due to the fact that they generate less noise and vibration, which can make them more comfortable to use.

Self Priming

Another advantage of lowrider hydraulic pumps is that they are self-priming. This means that they can start and stop without the need for an external priming pump.

Low Maintenance

Lowrider hydraulic pumps are also low maintenance, and they do not require a lot of care and upkeep. This makes them ideal for use in areas where maintenance costs need to be kept to a minimum.

Overall, there are many benefits to using lowrider hydraulic pumps. These pumps offer a number of advantages over conventional hydraulic pumps, and they are ideal for use in a variety of applications.

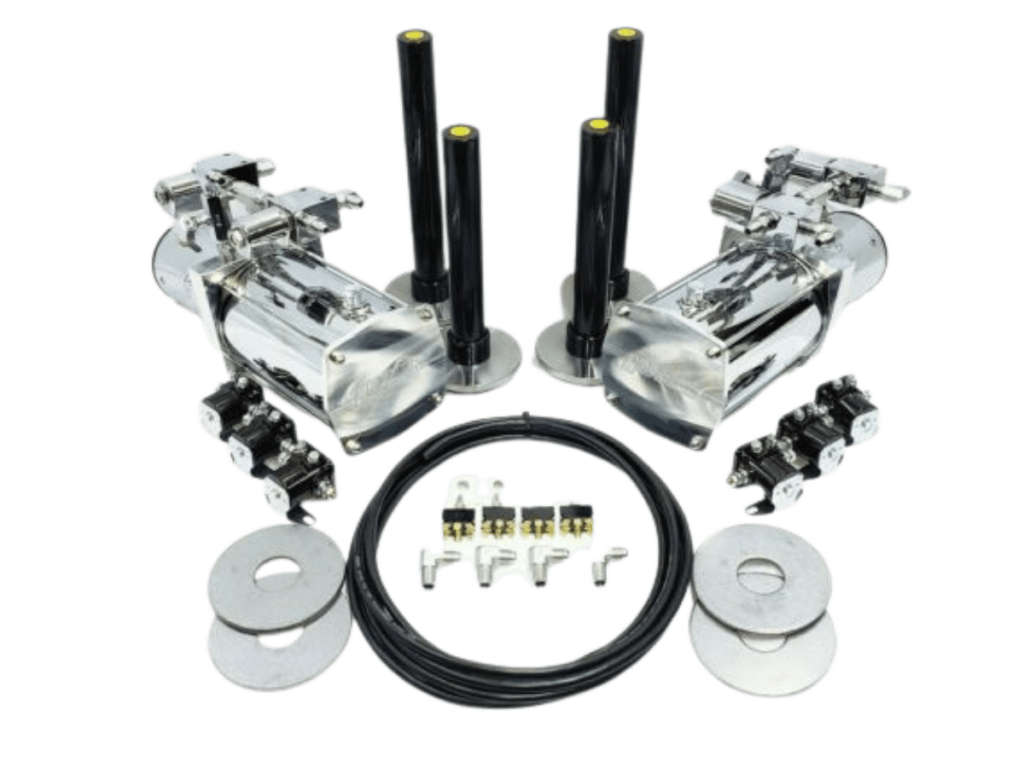

5. Main Components and Their Function

Lowrider hydraulic pumps are responsible for providing the pressure that lifts your car up and down. The main components of a lowrider hydraulic pump are the following:

The Reservoir

The reservoir is responsible for holding the hydraulic fluid that is used to power the pump. The reservoir is typically made from a durable material such as aluminum or steel, and it is usually located in the trunk of the car.

The Pump

The pump is responsible for pressurizing the hydraulic fluid and sending it to the cylinders. The pump is typically located in the engine bay of the car, and it is usually driven by a belt from the engine.

The Cylinders

The cylinders are responsible for lifting the car up and down. The cylinders are typically located in the suspension of the car, and they are connected to the hydraulic fluid lines from the pump.

Piston

The piston is responsible for moving the hydraulic fluid through the pump. The piston is typically located in the center of the pump, and it is usually driven by a crankshaft from the engine.

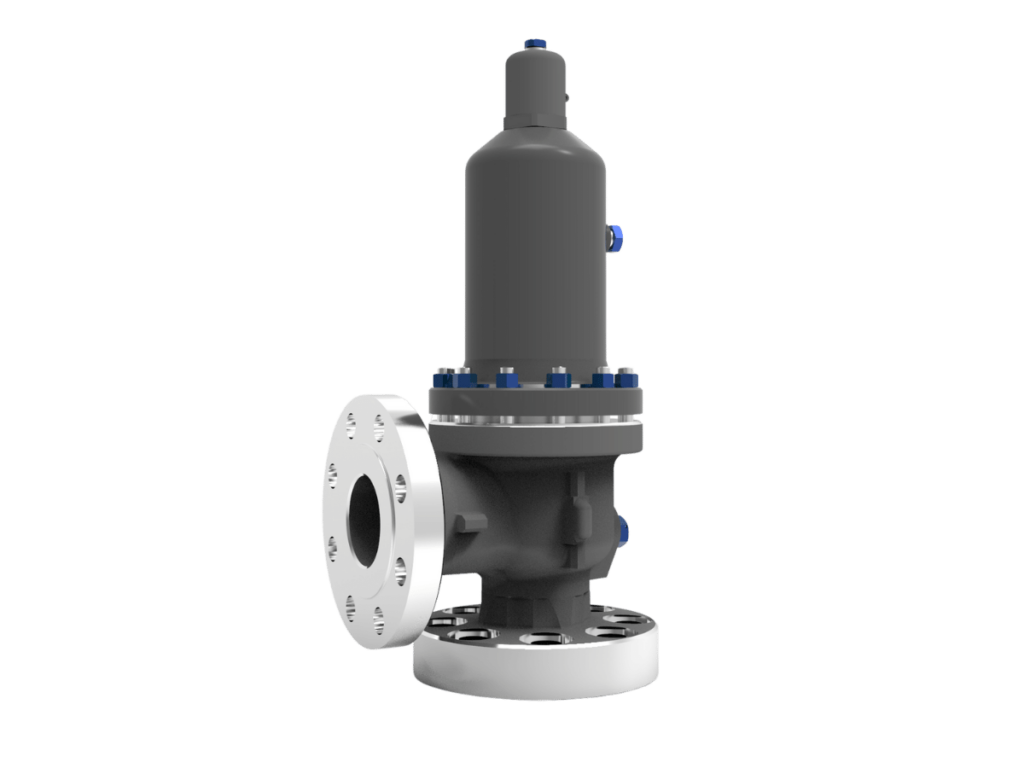

The Control Valve

The control valve is responsible for controlling the flow of hydraulic fluid to the cylinders. The control valve is typically located in the engine bay of the car, and it is usually operated by a lever from the dashboard.

Pressure Relief Valve

The pressure relief valve is responsible for releasing excess pressure from the system. The pressure relief valve is typically located in the engine bay of the car, and it is usually operated by a lever from the dashboard.

Pressure Gauge

The pressure gauge is responsible for measuring the pressure of the hydraulic fluid. The pressure gauge is typically located in the engine bay of the car, and it is usually operated by a lever from the dashboard.

Expansion Tank

The expansion tank is responsible for storing excess hydraulic fluid. The expansion tank is typically located in the trunk of the car, and it is usually made from a durable material such as aluminum or steel.

These are the main components of a lowrider hydraulic pump, and each one plays an important role in the operation of the pump. If you have any questions, contact Uphyd and we will be happy to help.

6. 7 Industry Application

Lowrider hydraulic pumps have a wide range of industry applications. They are commonly used in the following industry:

#1 Automotive

Lowrider hydraulic pumps are commonly used in the automotive industry. They are used to lift cars up and down, and they are also used to power other automotive components such as brakes and steering.

#2 Manufacturing

Lowrider hydraulic pumps are also commonly used in the manufacturing industry. They are used to power a variety of industrial machines, and they are also used to lift heavy objects.

#3 Construction

Lowrider hydraulic pumps are also commonly used in the construction industry. They are used to power a variety of construction equipment, and they are also used to lift heavy objects.

#4 Agricultural

Lowrider hydraulic pumps are also commonly used in the agricultural industry. They are used where the pumps are used to raise and lower irrigation booms. They are also used in some agricultural vehicles like combine harvesters.

#5 Mining

Lowrider hydraulic pumps are also used in the mining industry. They are used to power a variety of mining equipment like rock breakers and shovels. Lowrider hydraulic pumps help to make the mining process more efficient and effective.

#6 Marine

Lowrider hydraulic pumps are also used in the marine industry. They are used to power a variety of marine equipment like boat lifts and davits.

#7 Aviation

Lowrider hydraulic pumps are also used in the aviation industry. They are used to power a variety of aircraft components like brakes and landing gear. Lowrider hydraulic pumps help to make flying safer and more efficient.

Lowrider hydraulic pumps have a wide range of industry applications, and they are an essential part of many industries and businesses. If you have any questions about how lowrider hydraulic pumps can be used in your industry, contact Uphyd and we will be happy to help.

7. The Manufacturing Process

The manufacturing process for lowrider hydraulic pumps involves a number of steps, including:

Step#1 Design

The first step in the manufacturing process is the design of the pump. The designer works with the customer to understand their specific needs and requirements. They then create a detailed design of the pump that meets those needs.

Step#2 Casting

Once the design is complete, it is sent to the foundry where the pump is cast. The pump is cast from a variety of materials, including aluminum, steel, and iron.

Step#3 Machining

After the pump is cast, it is sent to the machine shop where it is machined to the precise specifications of the design. In this stage, the pump is also given any necessary finishes, such as plating or painting.

Step#4 Assembling

After the pump is machined, it is sent to the assembly department where it is assembled, In this stage, the pump is connected to the rest of the hydraulic system. All of the necessary valves and fittings are installed.

Step#5 Testing

Once the pump is assembled, it is sent to the testing department, where it is put through a series of tests like the pressure and flow tests. These tests ensure that the pump is able to meet the demands of the customer.

The manufacturing process for lowrider hydraulic pumps is a complex one, but it is necessary to ensure that the pumps are able to meet the needs of the customer. If you have any questions about how lowrider hydraulic pumps are made, contact Uphyd and we will be happy to help.

8. The Average Cost of Lowrider Hydraulic Pumps

in general, the average cost of most lowrider hydraulic pumps will fall in the range of $100 to $300. However, it can vary depending on a number of factors, such as the brand, the size, and the specific features. Some of the more expensive options may even exceed $500.

9. Where To Buy Lowrider Hydraulic Pumps

Looking for lowrider hydraulic pumps for sale? Lowrider hydraulic pumps can be purchased from a variety of places. Some of the most popular places to buy lowrider hydraulic pumps include:

Alibaba

Alibaba is a popular website that offers a wide range of products, including lowrider hydraulic pumps. There are a number of suppliers that offer pumps on this website, so it is important to compare prices and read reviews before making a purchase.

Made in China

Made in China is another website that offers a wide range of products, including lowrider hydraulic pumps. This is a B2B platform that offers a number of suppliers that offer pumps on this website.

Global Sources

Global Sources is a website that offers a wide range of products, including lowrider hydraulic pumps. This is another B2B platform that offers a number of suppliers that offer pumps on this website.

They are great options for those looking for high-quality products at a reasonable price.

DHgate

DHgate is a website that offers a wide range of products, including lowrider hydraulic pumps. This website offers a number of suppliers who offer pumps with a wide range of prices. It is important to compare prices and read reviews before making a purchase on this website.

When looking for hydraulic pumps for sale, it is important to compare prices and read reviews in order to find the best deal. These websites are great resources for those looking for high-quality products at a reasonable price.

10. 5 Buying Tips About Lowrider Hydraulic Pumps

When buying lowrider hydraulic pumps, there are a few things that you should keep in mind in order to get the best product for your needs. Here are a few tips to keep in mind:

#1 Type of Pump

It’s important to decide what type of pump you need. There are two main types of lowrider pumps: gear and vane. Gear pumps are more common and tend to be less expensive, but they can be noisy and may require more maintenance than vane pumps. Vane pumps, on the other hand, tend to be more reliable and longer lasting but may be more expensive.

#2 Size of Pump

The size of the pump is also an important consideration. hydraulic pumps come in a variety of sizes, from small to large. It’s essential to choose a size that is appropriate for the application. For example, if you are using a pump for a car, you will need a smaller pump than if you were using it for an SUV.

#3 Flow Rate

The flow rate is the amount of fluid that the pump can move per minute. It is important to choose a pump with a flow rate that is appropriate for the application. For example, if you are using the pump to power a car, you will need a higher flow rate than if you were using it to power a small boat.

#4 Pressure Rating

The pressure rating is the amount of pressure that the pump can generate and is another important consideration when choosing a low-rider hydraulic pump. If you need to generate a lot of pressure, you will need a pump with a high-pressure rating. If you only need to generate a small amount of pressure, you can choose a pump with a lower pressure rating.

#5 Material

The material that the pump is made of is also an important consideration. Pumps can be made from a variety of materials, including plastic, metal, and composite. It’s important to choose a material that is appropriate for the application. For example, if you are using the pump in a corrosive environment, you will need to choose a pump made from a corrosion-resistant material.

When choosing a lowrider hydraulic pump, it’s important to keep these factors in mind in order to choose the best pump for your needs. By taking the time to consider these factors, you can be sure that you’ll find the perfect pump for your application.

Conclusion

The Lowrider hydraulic pump is a great way to add style and functionality to your customers’ ride. With so many different brands and types on the market, it can be hard to know which one is right for your business. But with our guide, you should be able to find the perfect fit for your needs.

If you have any questions or need help picking out the right pump, contact us and we’ll be happy to assist you.

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.