PRODUCT FEATURES

Single Acting Pump Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide to Single Acting Pump

If you’re a business owner, chances are you’ve had to deal with pumps at some point. You may be wondering what exactly a single-acting pump is, and how it can benefit your business.

This ultimate guide will explain everything you need to know about single-acting pumps, including their features, key components, and their functions. We’ll also outline the steps you need to take when working with a manufacturer and some tips to keep in mind along the way.

So, whether you’re a business owner who’s new to pumps or you’re simply looking for more information, keep reading to learn more!

Table of contents

1. What Is a Single Acting Pump?

A single-acting pump is a type of positive displacement pump that uses a plunger to create a vacuum and move fluid. This was the first type of reciprocating pump developed, and it is still used in many applications today.

One advantage of the single-acting pump is its simplicity – it has only one moving part. This makes it easy to maintain and repair.

2. The Difference Between Single and Double Acting Pump

Single and double-acting pumps are two of the main types of hydraulic pumps. Here is a look at the difference between these two types of hydraulic pumps:

| Single Acting Pump | Double Acting Pump |

|---|---|

| typically used for lighter applications, such as lifting a small load or operating a simple machine | can generate force in both directions |

| only have one chamber, which limits the amount of force they can generate | can generate force in both directions |

| only have one chamber, which limits the amount of force they can generate | very efficient, using less energy than other types of hydraulic pumps |

Single-Acting Pump

A single-acting pump is a hydraulic pump3der. The single-acting pump is typically used for applications that only require fluid to be moved in one direction, such as lifting a load or moving a platform.

Double-Acting Pump

The double-acting pump can push fluid in both directions. This means that a double-acting pump can work as both an intake and exhaust pump, which is why it is sometimes called a “balanced” pump.

Check out this video to learn more about the difference between these two types of hydraulic pumps!

3. The Features of the Single Acting Pump

The single-acting pump is a versatile and powerful tool that can be used for a variety of applications. These are the features of this tool that make them an essential part of any shop or garage:

Portable

Single-acting pumps are often very portable, making them easy to move around and use in different locations. They are usually compact and lightweight, which makes them easy to transport and store.

Durable

Single acting plunger pumps are built to last, with many models featuring a heavy-duty construction that can withstand years of use. They are also often made from corrosion-resistant materials, making them ideal for use in harsh environments.

Easy to Use

Single-acting pumps are typically very easy to use, even for those with no prior experience. They often have a simple design that makes them easy to operate, and they can be used with a variety of different liquids.

Easy to Maintain

Single-acting pumps require very little maintenance, and they can often be cleaned with ease. They are also typically designed to be easy to repair, making them a great choice for those who need a reliable pump.

Little Energy Loss

Single phase hydraulic pumps typically have very little energy loss, making them an efficient choice for a variety of applications. This is because they only need to move liquid in one direction, which reduces the amount of energy required to operate them.

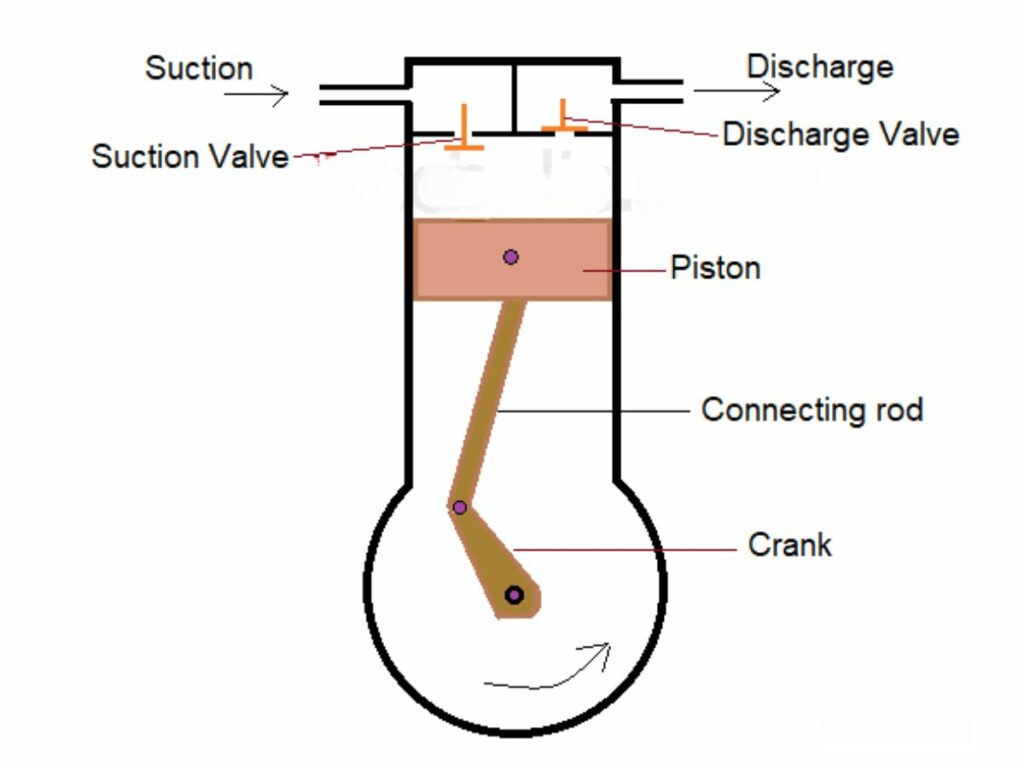

4. Key Components and Their Functions

Pumps are relatively simple machines, but they perform a variety of vital functions in many different industries. Let’s take a closer look at some of the key components that make up a typical single-acting pump, and see how they work together to keep things flowing smoothly.

Cylinder

The cylinder is the central component of any pump, and it’s where most of the action takes place. In a hydraulic pump single acting, the cylinder is typically divided into two chambers: the suction chamber and the discharge chamber.

Suction Chamber

The suction chamber is where fluid is drawn into the pump. It typically has a large surface area to allow for maximum fluid intake, and it’s connected to the inlet port of the pump.

Discharge Chamber

The discharge chamber is where fluid is delivered under pressure. It’s connected to the outlet port of the pump, and it typically has a smaller surface area than the suction chamber to help build up pressure.

Piston

The piston is a movable barrier that divides the cylinder into the suction and discharge chambers. In a single-acting pump, the piston is connected to a crankshaft, which drives it back and forth in the cylinder. As the piston moves, it draws fluid into the suction chamber and then forces it into the discharge chamber.

Pump Housing

The pump housing is a sturdy casing that encloses and supports the pump’s cylinder and other components. It helps to keep fluid from leaking out of the pump, and it also protects the internal components from external damage.

Shaft

The shaft is a rotating rod that runs through the center of the pump housing. It’s connected to the crankshaft, and it helps to support the piston as it moves back and forth in the cylinder.

Crankshaft

The crankshaft is a rotating shaft that’s connected to the piston. As it turns, it drives the piston back and forth in the cylinder, which draws fluid into the suction chamber and then forces it into the discharge chamber.

5. 6 Industry Application

Single-acting pumps are commonly used in a wide range of industries for various purposes. Here are 6 ways that single-acting pumps are utilized:

#1 Construction

One of the most important uses for single-acting pumps is in construction. In order to construct tall buildings, a large amount of concrete needs to be pumped to the upper floors. Single-acting pumps can pump concrete vertically, making them an essential part of the construction process.

#2 Agriculture

Single-acting pumps are also used in agriculture, specifically for irrigation. They are often used to pump water from wells or reservoirs and can be used to irrigate large fields.

#3 Manufacturing

Manufacturing facilities also make use of single-acting pumps. They are often used to pump fluids or gases during the manufacturing process. They are also often used as part of a large manufacturing system.

#4 Automotive

Single-acting pumps are also used in the automotive industry. They are often used to pump fluids such as oil, coolant, and brake fluid. They are also used in automotive applications such as power steering and air conditioning.

#5 Oil and Gas Industry

The oil and gas industry makes use of single-acting pumps in a variety of ways. They are used to pump oil and gas from wells, as well as to move them through pipelines. Single-acting pumps are also used in the refining process where they are used to pump liquids and gases.

#6 Mining

Single-acting pumps are also used in the mining industry. They are used to pump water from mines, as well as to move minerals and other materials through pipelines. Single-acting pumps are an essential part of the mining process.

6. The Average Cost of Single Acting Pump

Single-acting pumps typically cost between $200 and $300. This cost will depend on the specific model and brand of pump that you purchase. The price may also be higher if you purchase a pump with additional features.

If you’re looking for a more affordable option, you can always purchase a used single-acting pump. However, be sure to inspect the pump thoroughly before making your purchase. You’ll want to make sure that the pump is in good working condition and that all of the parts are included.

Additionally, buying directly from a manufacturer can often save you money on the cost of a single-acting pump. Many manufacturers offer discounts when you purchase bulk from them.

7. How to Work With Single Acting Pump Manufacturer

You’ve been thinking about working with a single-acting pump manufacturer, but you’re not sure how to get started. Here are the steps you need to take when working with a manufacturer:

Step#1 Have a Clear Understanding of Your Needs

What are you looking to achieve with the help of a single-acting pump manufacturer? What are your project specifications? Having a clear understanding of your needs will help you narrow down your search for the right manufacturer.

Step#2 Do Some Research

Once you know what you need, it’s time to start doing some research. Ask around for recommendations or look for manufacturers online. Once you’ve found a few potential manufacturers, it’s time to start comparing them.

Step#3 Ask for Quotes

Once you’ve found a few manufacturers that you’re interested in working with, it’s time to start requesting quotes. When requesting quotes, be sure to include all the specifications for your project. This will help the manufacturer give you an accurate quote.

Step#5 Negotiate Terms and Prices

Now that you’ve received quotes from the manufacturers, it’s time to start negotiating terms and prices. Be sure to get everything in writing so that there are no misunderstandings later on. This is also the best time to ask for any discount that you may be entitled to.

Step#6 Place Your Order and Pay Necessary Charges

After you’ve negotiated terms and prices with the manufacturer, it’s time to place your order. Before starting production, you will be asked to pay 50% of the total cost as a down payment. Once production is complete, you will be asked to pay the remaining 50%.

If you’ll be working with a manufacturer based in another country, you should also expect to pay shipping and import fees. These fees will usually cost you an additional 10% to 20% of the total cost.

Step#7 Inspect Your Goods and Give Feedback

Once you’ve received your goods, it’s important to inspect them to make sure that they meet your quality standards. If there are any problems with the goods, be sure to contact the manufacturer right away.

It’s also important to give feedback to the manufacturer so that they can improve their products and services. By working together, you can ensure that you’ll have a good working relationship for years to come.

8. Where to Source for a Reliable Manufacturer

Now that you know how to work with a single-acting pump manufacturer, it’s time to start sourcing for the right one. Here are a few places to check out to find reliable manufacturers:

Trade Shows

Trade shows are a great way to meet potential manufacturers and get a feel for their products. You can usually find trade shows that focus specifically on pumps and other fluid-handling equipment. This is a great opportunity to check out different manufacturers’ products and ask them questions in person.

Online Marketplaces

These platforms are a great way to compare different manufacturers side-by-side. You can read customer reviews and get a sense of each company’s reputation. These marketplaces also allow you to contact the manufacturers directly with any questions you may have.

Some of the popular online marketplaces are:

- Alibaba

- Global Sources

- IndiaMart

- Made-in-China

- EC21

9. 6 Buying Tips About Single Acting Pump

Here are 6 essential things to keep in mind to help you buy a single-acting pump for your business:

#1 Pump Capacity

The first thing you’ll need to consider is the capacity of the pump. How much water do you need to be able to move? The answer to this question will determine the size of the pump you’ll need to buy.

#2 Pump Design

There are two main types of single-acting pumps: piston and diaphragm. Piston pumps are more powerful and can move larger volumes of water, but they’re also more expensive. Diaphragm pumps are less powerful, but they’re cheaper and easier to maintain.

#3 Pump Material

Pumps are typically made from either cast iron or stainless steel. Cast iron pumps are more durable and resistant to corrosion, but they’re also more expensive. Stainless steel pumps are less durable, but they’re cheaper and easier to maintain.

#4 Pressure Rating

The pressure rating of a single acting 12v hydraulic pump is the maximum amount of pressure that the pump can handle. The higher the pressure rating, the more expensive the pump. The standard pressure rating ranges from 40 to 60 PSI.

#5 Flow Rate

The flow rate of a pump is the amount of water that the pump can move in a given period. The higher the flow rate, the more expensive the pump. Standard flow rates range from 4 to 12 GPM.

#6 Ease of Use

Of course, you’ll also want to consider the ease of use when choosing a single-acting pump. Some pumps are easier to use than others. Consider the features that are important to you and choose a pump that is easy to operate.

10. Conclusion

Single-acting pumps are versatile tools that can be used for a variety of applications. When buying these pumps for your business, be sure to work with a reputable manufacturer.

At Uphyd, we have years of experience manufacturing high-quality single-acting pumps. We offer a variety of models to choose from, from hydraulic power racks to different types of pumps. Contact us today to learn more about our products and how we can help you find the perfect single-acting pump for your needs!

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.