If you’ve been considering adding a power pack to your business, you may be wondering what the difference is between electric and hydraulic power packs.

In this guide, we’ll discuss the key differences between these two power packs so that you can make an informed decision about which type of power pack is right for your business.

So, if you’re ready to learn more about electric vs hydraulic power packs, let’s get started!

Table of contents

1. What Is Electric Power Pack

An electric power pack is a device that provides power to an electric motor. It typically consists of a battery, an inverter, and a controller. This is usually used in electric vehicles, but can also be used in other applications as well.

Electric power packs are becoming more popular as they offer a number of advantages over gas-powered engines. They are also more efficient, producing less pollution that’s why many industries are now using electric hydraulic power units instead of other types of engines.

2. How Does Electric Power Pack Work?

In order to understand how electric power racks work, here are the main components of an electric hydraulic power unit and their functions:

Battery

The battery is the heart of the power pack. It provides the energy that powers the electric motor. The three most common types of batteries used in electric power packs are lead-acid, nickel-cadmium, and lithium-ion.

Inverter

The inverter converts the direct current (DC) from the battery into an alternating current (AC). This is necessary because most electric motors run on AC. No matter what type of battery is used, an inverter is always needed to convert the DC to AC.

Controller

The controller regulates the flow of electricity from the battery to the electric motor. It ensures that the motor gets the correct amount of power and prevents it from being overloaded.

3. Electric Power Pack Applications

There are many different ways that electric hydraulic units can be used in industrial settings. Some of the most popular applications for these versatile devices include:

Powers Hydraulic Equipment

Electric power packs are often used to power hydraulic equipment. This can include everything from small tools and machinery to large-scale industrial equipment.

Manufacturing Operations

They are also often used in manufacturing operations. This can involve powering conveyor belts, operating presses, or even running production line machinery.

Maintenance and Repair

Electric power packs can also be used for maintenance and repair tasks. This can include things like powering welding equipment or providing backup power during an outage.

Construction Projects

Another common application for electric power packs is for construction projects. These devices can be used to power a variety of construction equipment, from small tools to large excavators.

Farm Machinery

These devices are also used in farm machinery. This can involve powering irrigation systems, operating crop harvesters, or even running a dairy operation.

Logging Operations

Similarly, electric power packs are often used in logging operations. This can include powering sawmills or running other types of heavy-duty equipment.

Automotive

Electric power packs are used in a variety of automotive applications, including engine testing, transmission assembly, and tire changing.

As you can see, there are many different ways that electric power packs can be used in industrial settings. If you’re looking to buy one for your business, contact us at Uphyd. We’ll be happy to help you find the perfect electric power pack for your needs.

4. Advantages of Electric Power Pack

There are many benefits to using electric power packs, which is why they are becoming increasingly popular. Some of the main benefits include:

Convenience

Electric power packs are very convenient to use. They can be easily transported and stored, and they don’t require any special training to operate.

Flexibility

Another advantage of electric power packs is that they are very flexible. They can be used for a variety of different applications, which makes them ideal for businesses that have multiple needs.

Efficiency

Electric power packs are much more efficient than gas-powered engines. This means that they use less energy to do the same amount of work. As a result, they can help to save your business money on energy costs.

Environmental Friendliness

Not only are electric power packs more efficient than other types, but they also don’t produce emissions and can help your business go green. This is good for the environment and can also help to improve your company’s image.

Quiet Operation

Another advantage of electric power packs is that they run much more quietly than other types. This can be beneficial if you’re looking to reduce noise pollution in your workplace.

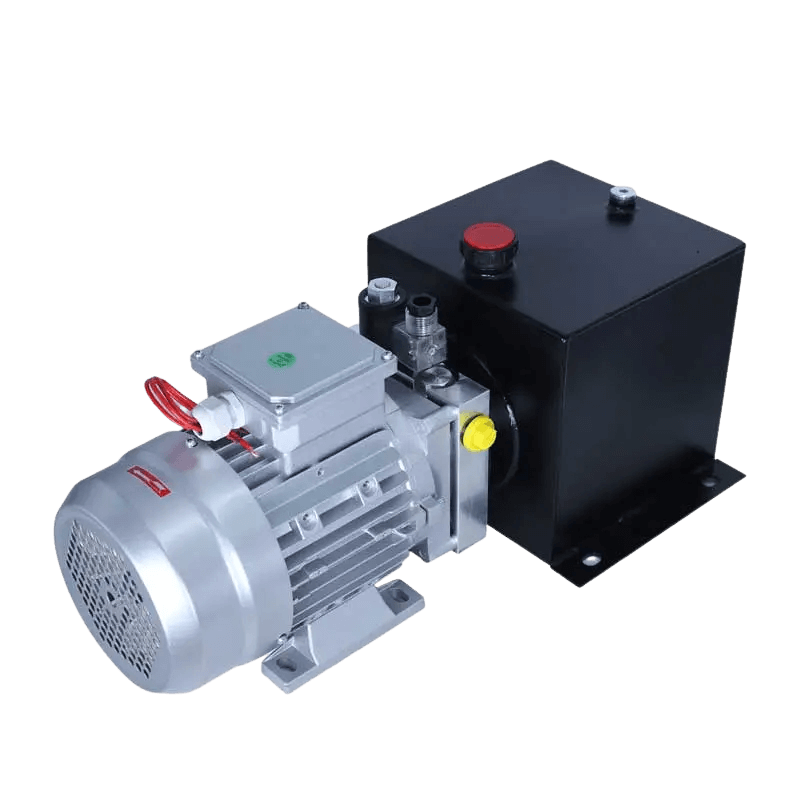

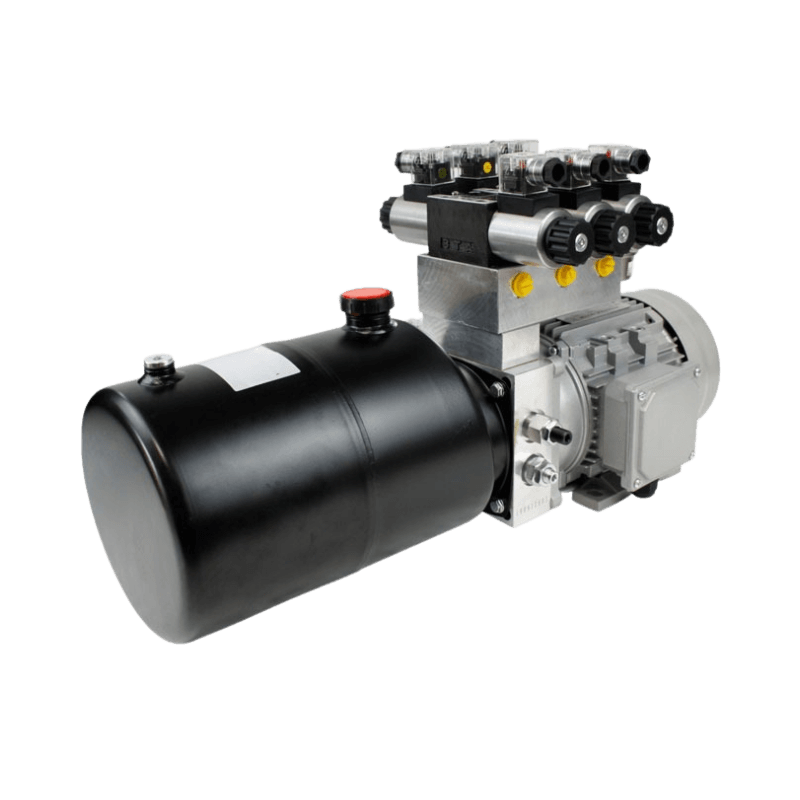

5. What Is a Hydraulic Power Pack?

A hydraulic power pack is a self-contained unit that provides the power for a hydraulic system. Hydraulic power packs are used in a variety of applications, including construction equipment, automotive manufacturing, and material handling. In most cases, hydraulic power packs are custom-built to meet the specific needs of the application.

6. How Does Hydraulic Power Pack Work?

To better understand how hydraulic power packs operate, here are the main components of these systems and how they work together:

Hydraulic Fluid

This is the lifeblood of the system and it is typically oil-based. The fluid is stored in a reservoir and it is pumped through the system by the pump.

Pump

The pump is responsible for moving the hydraulic fluid through the system. It is powered by an electric motor or a gasoline engine.

Reservoir

The reservoir stores the hydraulic fluid. It is typically made from steel or aluminum and it has a fill level indicator to help you keep an eye on the fluid level.

Valves

Valves are used to control the flow of hydraulic fluid through the system. They are typically operated by a lever or a knob.

There are two types of valves in a hydraulic power pack system: directional control valves and pressure relief valves. Directional control valves direct the flow of fluid to the hydraulic cylinders or motors. Pressure relief valves help to regulate the pressure in the system.

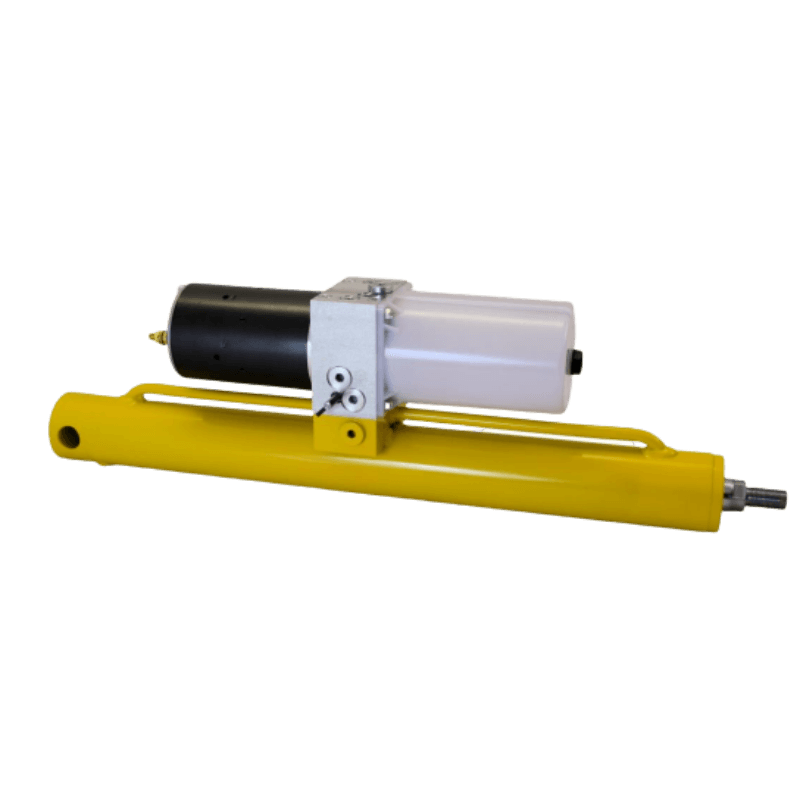

Hydraulic Cylinders

Hydraulic cylinders are used to produce linear motion. They are activated by the directional control valves.

Cooling Fans

Some hydraulic power pack systems have cooling fans to help keep the fluid cool. This is important because if the fluid gets too hot, it can break down and cause damage to the system.

Here’s a video of how hydraulic power pack works:

7. Hydraulic Power Pack Applications

Here are the common industrial applications for hydraulic power packs:

Manufacturing

Hydraulic power packs are used in many industrial manufacturing settings, such as stamping presses and injection molding machines. The power pack provides the hydraulic pressure and flow that operate the machine.

Construction

Hydraulic power packs are used in construction equipment, such as excavators and bulldozers. The power pack powers the hydraulic cylinders that operate the arms and bucket of the excavator, or the blade of the bulldozer.

Mining

Hydraulic power packs are used in mining equipment, such as rock crushers and shovel loaders. The power pack provides the hydraulic pressure and flow that operate the machine.

Automotive Parts

Hydraulic power packs are used in automotive parts manufacturing, such as in the production of transmissions and brakes.

Material Handling Solutions

These power packs are used in many different types of material handling solutions, such as scissor lifts, dock levelers, and aerial work platforms. They provide the hydraulic power needed to operate the machine.

8. Advantages of Hydraulic Power Pack

There are many advantages of using a hydraulic power pack over other power sources. Here are the reasons why you should consider using one:

Efficient

Hydraulic power packs are very efficient. They can convert up to 90% of the energy they receive into usable power, compared to only 40% to 50% for electric motors.

Compact

Hydraulic power packs are very compact. They can be used in tight spaces where other power sources would not be able to fit.

Versatile

These power packs come in a wide range of power voltage for a wide variety of applications, such as lifting, powering hydraulic tools, and operating machinery. The most common voltages for these tools are:

- 110 volt hydraulic power unit

- 12 volt hydraulic power unit

- 120 volt hydraulic power unit

- 220 volt hydraulic power unit

- 24 volt hydraulic power unit

Quiet

Hydraulic power packs are very quiet. They produce little noise when operating, making them ideal for use in noise-sensitive areas.

Cost-Effective

These power packs are also very efficient at transferring energy. They can transfer energy more efficiently than electric motors, making them more cost-effective to operate in the long run.

Safe to Use

Hydraulic power packs provide a high level of safety. When used correctly, they pose little risk to those working with them or to the environment.

9. The Key Difference Between Electric and Hydraulic Power Packs

Hydraulic power packs and electric power packs are two common types of power packs used in a variety of applications. While they both serve the same basic purpose, several key differences between them should be considered when choosing which type of power pack is right for a particular application. Let’s take a closer look at these differences.

| Electric Power Packs | Hydraulic Power Packs |

|---|---|

| use electrical current to generate power | use pressurized fluid to generate power |

| often have more complex control systems that allow for more precise regulation of power output | typically use an on/off switch |

| typically have fewer moving parts and require less frequent maintenance | generally require more frequent maintenance than electric units, due to the need to change fluids and filter elements on a regular basis |

| often have a higher flow rate | generally require more frequent maintenance than electric units, due to the need to change fluids and filter elements on a regular basis |

| vary depending on several factors, such as the size and features of the unit | tend to be more expensive than electric units |

Power Source

One of the most important differences between hydraulic and electric power packs is the source of power. 220v hydraulic power units use pressurized fluid to generate power, while electric power packs use electrical current. This can have a significant impact on the amount of power that can be generated, as well as the overall efficiency of the unit.

Machine Control

Another key difference is how the two types of units are controlled. Hydraulic power packs typically use an on/off switch, while electric power packs often have more complex control systems that allow for more precise regulation of power output. This can be an important consideration when choosing a power pack for a particular application.

Maintenance Requirements

Hydraulic power packs generally require more frequent maintenance than electric units, due to the need to change fluids and filter elements on a regular basis. Electric units, on the other hand, typically have fewer moving parts and require less frequent maintenance.

Pressure Rating and Flow Rate

Hydraulic power packs are typically able to generate higher pressures than electric units, making them ideal for applications that require high levels of power. Electric units, on the other hand, often have a higher flow rate and can be better suited for applications that require a large volume of power over a shorter period of time.

Cost

The cost of an electric over hydraulic power unit can vary depending on several factors, such as the size and features of the unit. In general, however, hydraulic units tend to be more expensive than electric units.

10. 4 Buying Tips When Choosing Between Electric and Hydraulic Power Packs

When choosing between an electric and hydraulic power pack, there are a few important factors to consider. Here are 4 of them:

#1 Power Requirements

First, think about the power requirements of your application. Hydraulic power packs are more powerful than electric ones, so if you need a lot of torque or lifting capacity, hydraulic is the way to go. Electric power packs are more suitable for lighter applications.

#2 Environment

You should also consider the environment in which the power pack will be used. If it will be exposed to dust, dirt, or water, electric is a better option because it is less likely to be damaged by these elements. Hydraulic power packs are more durable, but they can be more difficult to keep clean.

#3 Application

If it will be used frequently, electric is a better choice because it is less likely to overheat with frequent use. Hydraulic power packs can overheat if they are used too often, so if you only need occasional use, they may be a better option.

Additionally, hydraulic power packs are better suited for heavy-duty applications, while electric power packs are more versatile and can be used for a wider range of applications.

#4 Budget

Finally, consider your budget when choosing between an electric and hydraulic power pack. Hydraulic power packs are typically more expensive than electric ones, but they offer more power and durability.

11. Conclusion

Now that you know the ins and outs of these two power packs, it’s time to get out there and start shopping for the perfect one for your needs. You need to work with a reputable manufacturer to ensure you’re getting a quality product.

At Uphyd, we have a team of experts who can help you select the right power pack for your application. We also offer a wide range of hydraulic power packs for sale, so we’re sure to have the perfect one for you. Contact us today to learn more about our products and services.