When it comes to pumps, there are two main types: electric and hydraulic. But what’s the difference between them? And which one is better for your business?

In this blog post, we’ll take a look at the basics of electric and hydraulic pumps, their applications, advantages, and key differences. By the end of this post, you should have a good idea of which type of pump is best for your business.

So, without further ado, let’s get started!

Table of contents

1. Electric Pump: The Basics

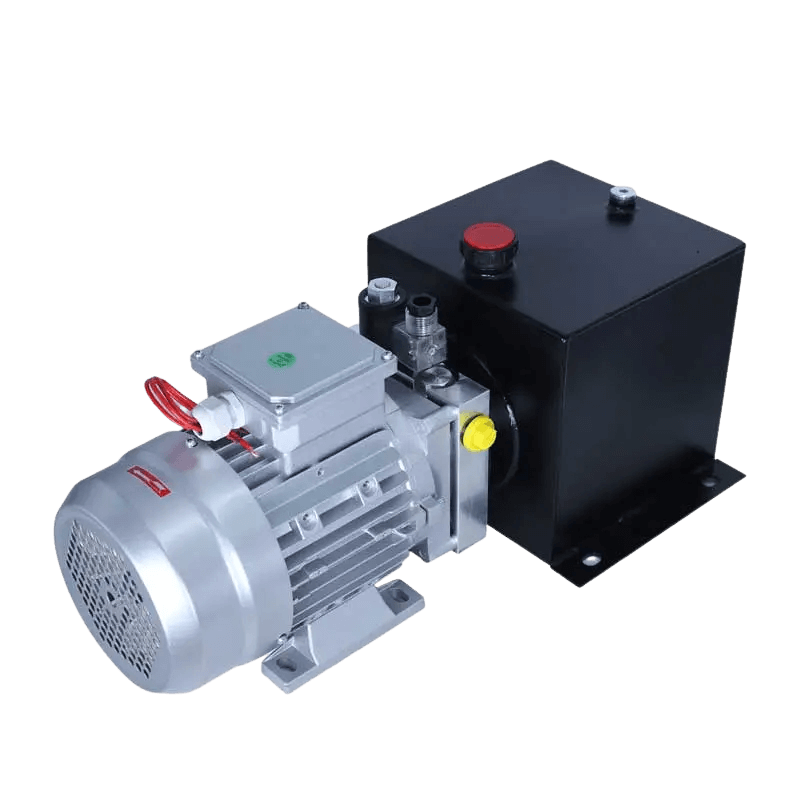

An electric pump is a device that uses an electric motor to move fluid. The electric pump has many applications, including in hydraulic systems.

The electric pump consists of 3 main parts: the motor, the pump body, and the inlet and outlet ports. The electric motor is responsible for turning the pump shaft, which causes the pump body to rotate. This, in turn, creates a vacuum on the inlet side and pressure on the outlet side of the pump. The inlet and outlet ports allow fluid to enter and exit the pump body.

Electric pumps are available in a variety of sizes and shapes and can be used to move various types of fluids. They are commonly used in hydraulic systems to power hydraulic motors or actuators.

2. How Does Electric Pump Work?

The electric pump work by using an electric motor to generate hydraulic power. This force is then used to move the pump’s pistons. The movement of the pistons creates suction that pulls fluid from the reservoir and into the pump.

3. Electric Pump Applications

Electric pumps are used for many purposes in both residential and commercial settings. Some of the most common applications are:

#1 Flood Control

Electric pumps are often used to help control flooding, by pumping water out of low-lying areas or back into reservoirs.

#2 Sewage Removal

Large electric dump pumps can be used to remove sewage from buildings or towns, either to treatment facilities or just to empty out tanks.

#3 Irrigation

Farmers and gardeners often use electric pumps to irrigate their crops, by pumping water from wells or rivers to the desired location.

#4 Pool Filtration

In order to keep swimming pools clean, they must be constantly filtered. Electric pumps are often used for this task.

#5 Cooling Systems

Commercial and industrial buildings often have large cooling systems that use electric pumps to circulate refrigerant fluid.

#6 Firefighting

Some fire trucks contain electric pumps that can be used to pump water directly from a fire hydrant or other water source. This can be used to fight fires or to cool down overheated buildings.

These are just some of the many ways that electric pumps are used in today’s world. If you have a need for a pump, there’s likely an electric option that can suit your business needs.

4. Advantages of Electric Pump

Electric pumps offer several advantages. Here are just a few of the reasons why you might want to consider an electric pump for your next purchase:

Save Time And Energy

Electric pumps can save a lot of time and energy. They are faster than manual pumps and the process is much easier. The user doesn’t have to worry about pumping the handle up and down or trying to keep the liquid from spilling.

Portable And Easy To Use

Electric pumps are also very portable. They can be taken wherever there is an outlet to plug them in. They are easy to use and can be operated with one hand. This is a big advantage especially if the operator is disabled or has a condition that makes it difficult to use a manual pump.

No Mess

Another advantage of electric pumps is that they don’t make a mess. There is no spillage, and the user doesn’t have to worry about getting dirty. The process is clean and efficient.

Avoid Muscle Fatigue

Using an electric pump can also help avoid muscle fatigue. Electric pumps take all of the work out of the process, so the user doesn’t have to worry about getting tired. Additionally, electric pumps can be used for a longer period of time without causing fatigue.

Safe And Reliable

Electric pumps are also safe and reliable. They are less likely to break down and they can be used in a variety of settings. Electric pumps are also less likely to cause injuries because the user doesn’t have to worry about losing their grip or applying too much pressure.

Cost-Effective

Electric pumps are also cost-effective. They are less expensive and they last longer. Additionally, electric pumps can be used in a variety of settings, so the user doesn’t have to worry about buying multiple pumps.

Easy To Maintain

Finally, electric pumps are easy to maintain. They don’t require a lot of upkeep and they can be used for a long time without issue. Additionally, electric pumps are easy to troubleshoot if there are ever any problems.

These are just a few of the advantages of electric pumps. If you are thinking about purchasing a pump, then you should definitely consider an electric pump. They offer a number of benefits that can make life easier.

5. Hydraulic Pump: The Basics

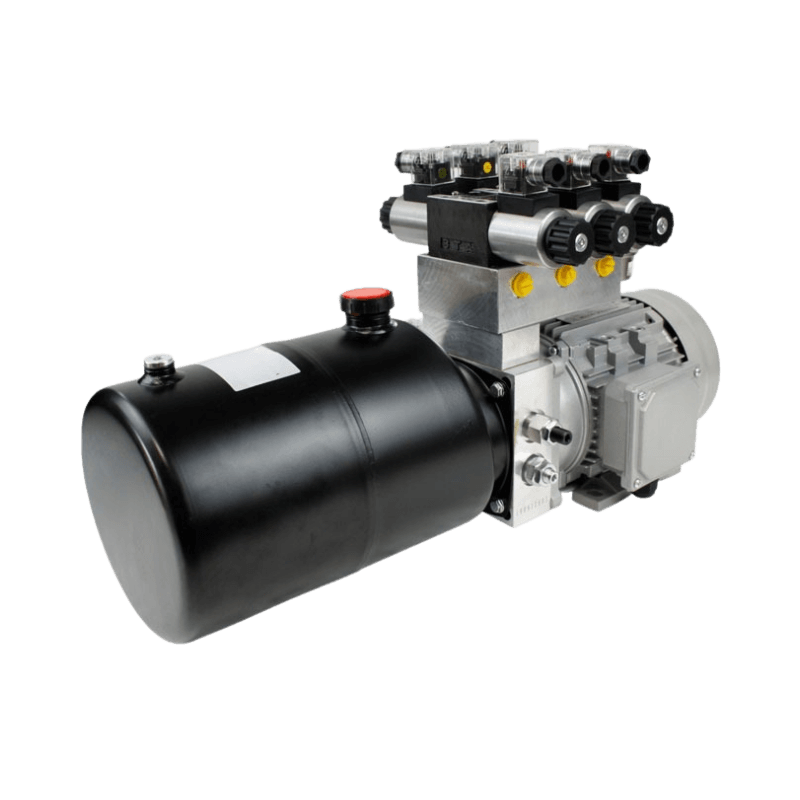

A hydraulic pump is a device that uses pressurized fluid to perform work. The most common use of a electric driven hydraulic pump is to create motion by transferring energy from one component to another. There are many different types of hydraulic pumps, but they all share some basic components and principles.

Most electric motor driven hydraulic pumps consist of 3 main parts: the pump body, the inlet, and the outlet.

- The pump body is the main part of the pump, and it contains the cylinders, pistons, and other components that create the pressurized fluid.

- The inlet is where the fluid enters the pump

- The outlet is where it exits.

The basic principle behind a hydraulic pump is that when one piston moves down, it creates a decrease in pressure that causes fluid to be drawn into the pump through the inlet. When the second piston moves up, it creates an increase in pressure that causes the fluid to be forced out of the outlet. This cycle repeats continuously as long as the pump is running.

6. How Does Hydraulic Pump Work?

The hydraulic pump work by using mechanical energy to create a pressure difference that forces the liquid through a small orifice. It is this pressure difference that allows the hydraulic pump with electric motor to do work. The higher the pressure difference, the greater the force that can be exerted on the liquid, and the greater the amount of work that can be done.

7. Hydraulic Pump Applications

There are a number of hydraulic pump applications that can be used in a variety of industries. Some of the most common applications include:

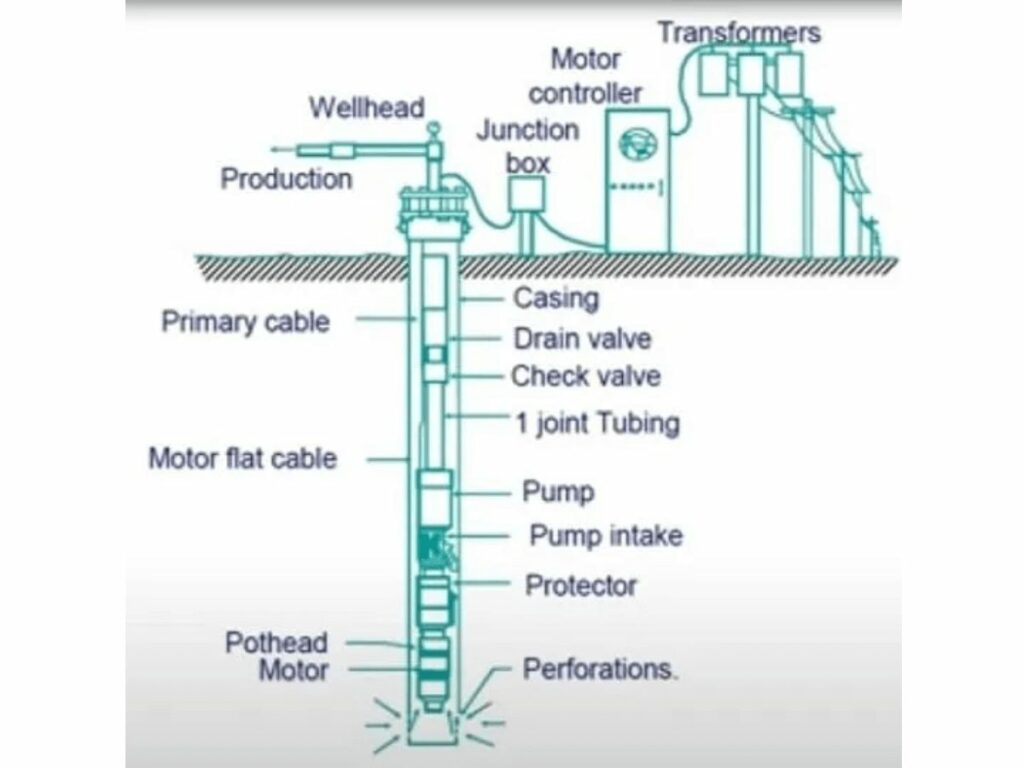

Pumping Oil Or Other Fluids Through Pipelines

Hydraulic pumps are commonly used to pump oil or other fluids through pipelines. This application is especially common in the oil and gas industry.

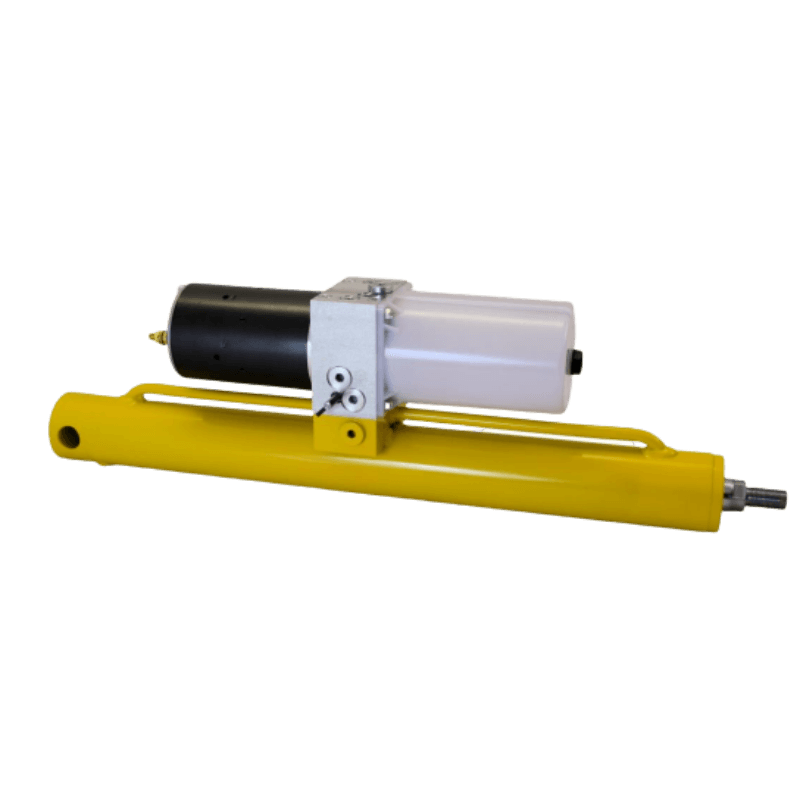

Powering Excavators

Hydraulic pumps are used to power the hydraulic cylinders that operate excavators. It is the pressure generated by the small electric hydraulic pump that allows the excavator to move its bucket and arm.

Powering Cranes

Cranes rely on electric hydraulic press pumps to generate the pressure needed to operate their lifting mechanisms. Without a battery operated hydraulic pump, a crane would not be able to function.

Operating Forklifts

The cordless hydraulic pump is responsible for powering the hydraulic cylinders that operate the lift mechanism on a forklift.

Operating Garbage Trucks

Garbage trucks also rely on high pressure electric hydraulic pumps to power their lifting mechanisms. The hydraulic pump is used to raise and lower the dumpster on the back of the truck.

Supporting Maritime Operations

Hydraulic pumps are used in a variety of maritime applications. They are commonly used to operate the steering systems on ships and to power the winches that are used to launch and retrieve boats from the water.

Serving As Emergency Backup Power Sources

Hydraulic pumps can also be used as emergency backup power sources. In the event of a power outage, a portable electric hydraulic pump can be used to generate the pressure needed to operate critical systems like elevators and fire suppression systems.

These are just a few of the many applications that double acting electric hydraulic pumps can be used for. This versatile piece of equipment is an essential part of many industries because of its ability to generate high levels of pressure.

8. Advantages of Hydraulic Pump

A hydraulic pump has a number of advantages over other types of pumps. Here are just a few:

Powerful

A hydraulic gear pump with electric motor is powerful because it uses fluid pressure to transmit energy. This makes it a great choice for moving large amounts of fluid or lifting heavy loads. It can also be used to generate high pressures for tasks such as breaking or welding.

Versatile

A hydraulic driven vacuum pump is very versatile because it can be used in a wide variety of applications. It can be used for lifting, moving, or pressurizing fluids. It is also commonly used in construction and manufacturing.

Easy To Control

A brushless hydraulic pump is easy to control because the amount of fluid that is pumped can be easily regulated. This makes it a great choice for applications where precision is important.

Reliable

An AC hydraulic pump is a very reliable piece of equipment because it has few moving parts. This means that there is less that can go wrong with it. It is also very durable and can withstand a lot of wear and tear.

Low Maintenance

A hydraulic pump is a low maintenance because it does not require a lot of upkeep. It is also easy to repair if it does break down.

Affordable

A hydraulic pump is an affordable piece of equipment because it is not very expensive to purchase or maintain. This makes it a great choice for businesses on a budget.

Environmentally Friendly

A hydraulic pump is an environmentally friendly piece of equipment because it does not use any fossil fuels. This makes it a great choice for businesses that are trying to be more green.

Quiet

A hydraulic pump is a very quiet piece of equipment because it does not have any moving parts. This makes it a great choice for businesses that are looking for a low-noise solution.

These are just a few of the advantages of hydraulic pumps. Due to these reasons, it’s no wonder that they are so popular. If you need a versatile, powerful, and affordable piece of equipment, then a hydraulic pump is the perfect choice for you.

9. The Key Differences Between Electric and Hydraulic Pumps

While both electric and hydraulic pumps are used for a variety of purposes, there are some key differences between the two types of pumps that should be considered when making a purchase. Let’s break down the key differences between electric and hydraulic pumps:

| Electric Pumps | Hydraulic Pumps |

|---|---|

| do not require a power source that can be damaged by the elements | rely on a power source that can be compromised by extreme temperatures or other factors |

| electric motors can maintain a constant speed even under heavy loads | hydraulic motors will slow down when overloaded |

| can be used underwater | can be damaged by water |

| able to create a magnetic field that can interact with the rotor to generate torque | rely on fluid pressure to create movement |

Harsh Environments

One key difference between electric and hydraulic pumps is that electric pumps can be used in harsh environments, while hydraulic pumps cannot. This is because electric pumps do not require a power source that can be damaged by the elements, whereas hydraulic pumps rely on a power source that can be compromised by extreme temperatures or other factors.

Stalling Loads

Another key difference between electric and hydraulic pumps is that electric pumps can handle stalling loads, while hydraulic pumps cannot. This is because electric motors can maintain a constant speed even under heavy loads, whereas hydraulic motors will slow down when overloaded.

Underwater Service

Another key difference between electric and hydraulic pumps is that electric pumps can be used underwater, while hydraulic pumps cannot. This is because electric motors are not affected by water, whereas hydraulic motors can be damaged by water.

Generating Torque

One final key difference between electric and hydraulic pumps is that electric motors can generate torque, while hydraulic motors cannot. This is because electric motors are able to create a magnetic field that can interact with the rotor to generate torque, whereas hydraulic motors rely on fluid pressure to create movement.

Thus, when choosing between an electric or hydraulic pump, it is important to consider the environment in which the pump will be used, the type of load that will be placed on the pump, and whether or not the pump needs to be used underwater. This way, you can ensure that you select the pump that is best suited for your needs.

10. 4 Buying Tips When Choosing Between Electric and Hydraulic Pumps

When choosing between electric and hydraulic pumps, there are a few things you should keep in mind:

#1 Purpose

What do you need the pump for? If you need it for a specific application that requires high pressure, then a DC powered hydraulic pump is likely your best bet. On the other hand, if you need a pump that’s more versatile and can be used in a variety of settings, an electric pump may be the way to go.

#2 PSI

How much pressure do you need the pump to generate? If you need a high-pressure pump, then a hydraulic pump is likely your best bet. On the other hand, if you only need a low-pressure pump, an electric pump may be the way to go. Here are some examples of PSI:

- 10000 psi

- 3000 psi

- 4000 psi

#3 Volt

How much power do you need the pump to have? If you need a high-power pump, then an electric pump is likely your best bet. On the other hand, if you only need a low-power pump, a hydraulic pump may be the way to go. Here are some examples of volts:

- 12 volt

- 24 volt

- 110 volt

- 220 volt

- 240 volt

#4 Flow Rate

The flow rate indicates how much liquid the pump can move in a given period of time. If you need a pump that can handle a large volume of liquid, then you’ll want to choose a model with a high flow rate.

Electric vs hydraulic pumps – it really depends on your needs. If you need a high-pressure pump for a specific application, then a hydraulic pump is likely your best bet. However, if you need a more versatile pump that can be used in a variety of settings, an electric pump may be the way to go. Consider these factors when making your decision.

Alternatively, if you’re still not sure which type of pump is right for you, contact us at Uphyd and we’d be happy to help you choose the best option for your needs. Uphyd is a leading provider of hydraulic and electric pumps. We offer a wide selection of pumps to suit any application. Contact us today to get started!

11. Conclusion

So there you have it – the electric vs hydraulic pump debate in a nutshell. Both types of pumps have their pros and cons, so which one is right for your business? That’s something only you can answer. But no matter what type of pump you choose, remember that at the end of the day it’s all about getting the right product for your business.

If you have any questions or need more information on electric vs hydraulic pumps, don’t hesitate to contact us at Uphyd. We’re always happy to help.