If you’re in the market for a new power pack, you’ve probably heard of both electric and hydraulic cylinders. But what’s the difference? And which one is right for your business?

In this blog post, we break down everything you need to know about electric vs hydraulic cylinders – so you can make the best decision for your business. We also debunk some of the most common myths about each type of power pack, to help you make an informed decision.

So if you’re ready to learn more about electric vs hydraulic cylinders, let’s get started!

Table of contents

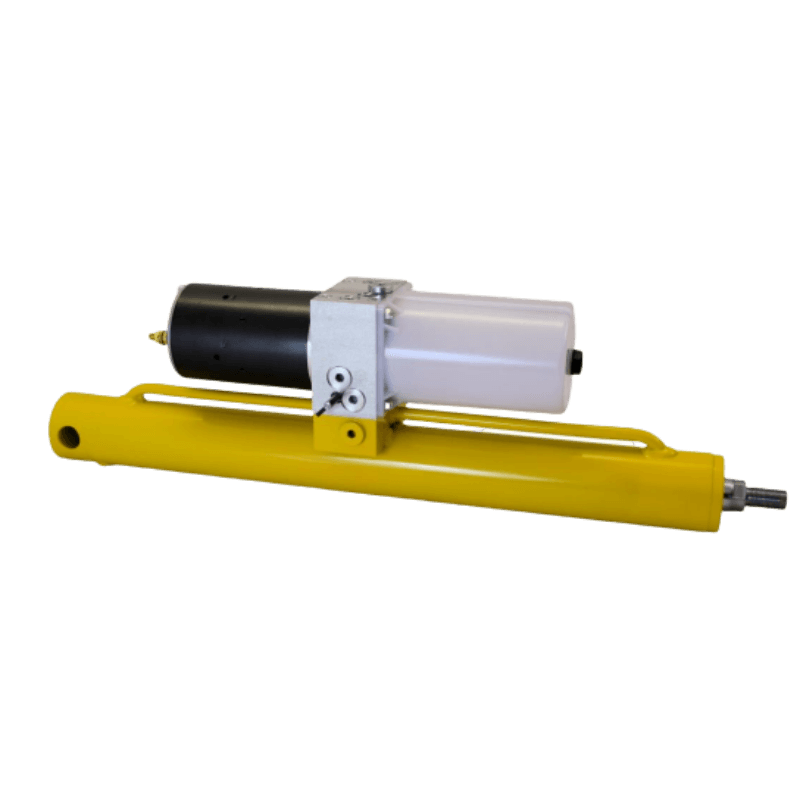

1. Electric Cylinder: The Basics

The electric cylinder is a type of linear actuator that uses electricity to create motion in a straight line. Electric cylinders are often used in automation applications where high force and/or speed are required.

The electric cylinder is a device that takes an electrical input and converts it into linear motion. The motion can be either linear extension (extending the rod) or retraction (pulling the rod back in).

Electric cylinders are used in a wide variety of applications, including automotive assembly, robotics, and material handling. They are also used in a number of industrial and commercial applications such as machine tools, presses, and injection molding machines.

2. How Does Electric Cylinder Works?

Electric cylinders work by using an electric motor to move a piston inside a cylindrical housing. The piston is connected to a rod, which extends out of the cylinder. When the electric motor is activated, it creates rotational motion that is transferred to the piston via a series of gears. This linear motion moves the rod, which can be used to actuate a load.

3. Electric Cylinder Applications

When it comes to electric hydraulic lift cylinder applications, there are quite a few different ways these handy tools can be used. Here are just a few examples:

Lifting and Moving Heavy Objects

One of the most common electric cylinder applications is using them to lift and move heavy objects. This is because electric cylinders are incredibly strong and can generate a lot of torque. This makes them perfect for moving heavy loads from one place to another, or even for lifting them up off the ground.

Adjusting Heavy Machinery

Another common application for electric lift cylinders is adjusting heavy machinery. If a machine is not level or needs to be moved slightly, an electric cylinder can be used to make the adjustment. This is often done in factories or warehouses where there is a lot of heavy machinery.

Opening and Closing Doors

Electric cylinders can also be used to open and close doors. This is a common application for hospitals, as it allows nurses and doctors to move quickly between rooms without having to open and close doors manually. It can also be used in other places where it’s important to keep the flow of traffic moving quickly.

These are just a few of the many different electric cylinder applications. As you can see, they are incredibly versatile tools that can be used in a wide variety of settings.

4. Advantages of Electric Cylinder

The electric cylinder is an innovative device that has a number of advantages over traditional hydraulic cylinders. Here are some of the main benefits of using an 12 volt lift cylinder:

Increased Efficiency

Electric cylinders are more efficient than hydraulic cylinders because they don’t rely on oil or other fluids to operate. This means that there is no need to regularly change or top up the fluid, which can save you time and money.

Greater Control

Electric cylinders offer greater control than hydraulic cylinders. This is because you can easily adjust the speed and force of the cylinder, which gives you more control over the movement of your load.

Smaller in Size

Small electric hydraulic cylinders are smaller in size than hydraulic cylinders, which means they take up less space and are more convenient to use.

Safer to Use

12 volt electric lift cylinders are also safer to use than hydraulic cylinders. This is because there is no risk of oil leaks, which can be dangerous. Electric cylinders are also less likely to overheat, which can be a hazard with hydraulic cylinders.

Environmentally Friendly

Electric cylinders are more environmentally friendly than hydraulic cylinders because they don’t use oil or other fluids. This means that there is no risk of oil spills, which can be damaging to the environment.

These are just some of the advantages of electric cylinders. With so many benefits, it’s no wonder that they are becoming increasingly popular for a wide range of applications.

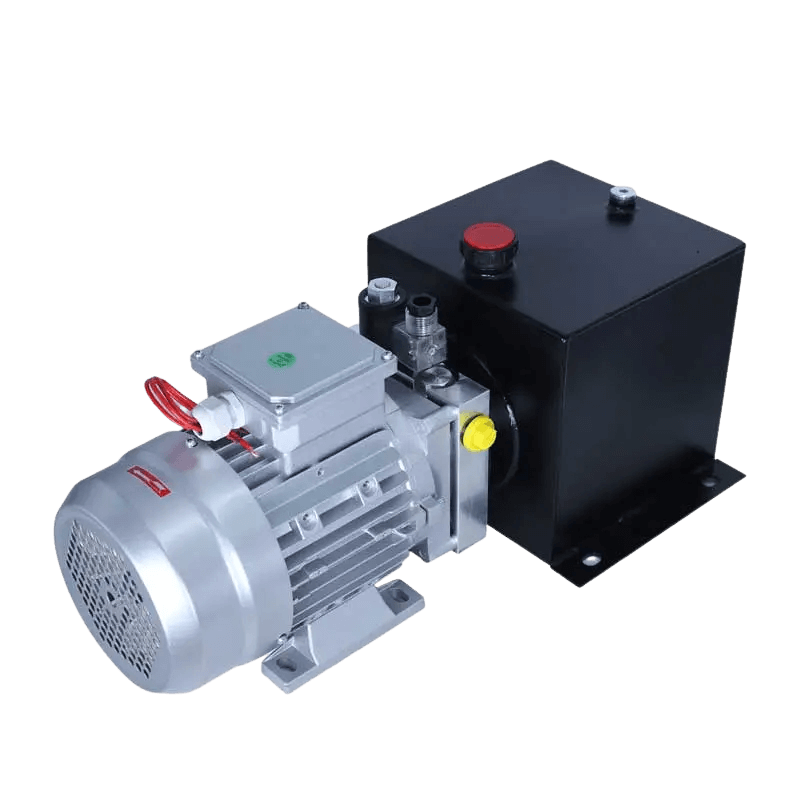

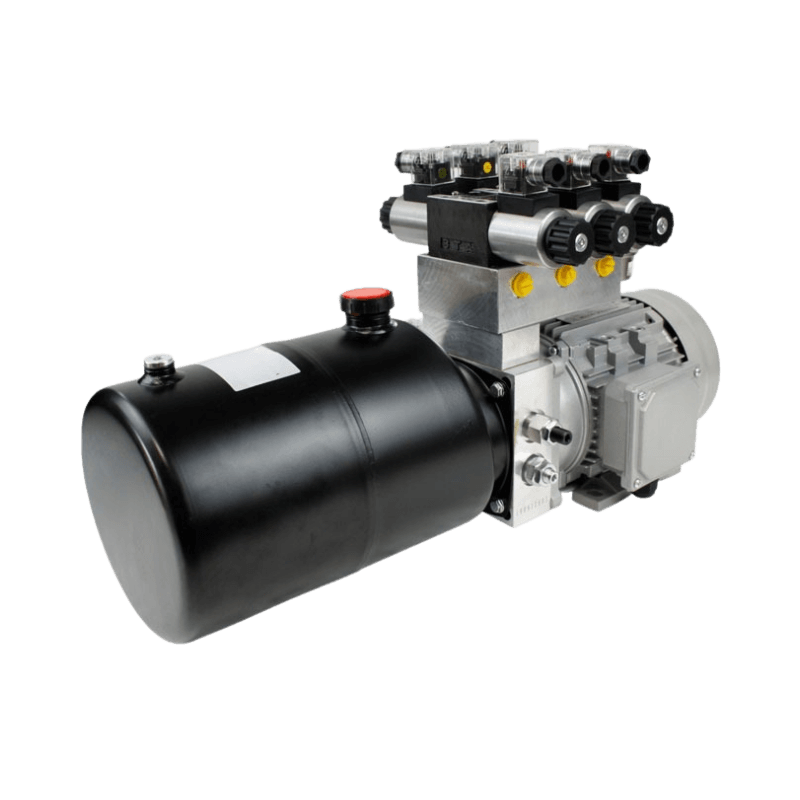

5. Hydraulic Cylinder: The Basics

A hydraulic cylinder is a mechanical actuator that is used to give linear force and motion. The cylinder consists of a piston that is attached to a rod, which in turn is connected to a mechanical component.

The piston is sealed at both ends so that fluid can’t escape, and the rod seal prevents fluid from entering the rod end. When fluid is forced into the cylinder, it pushes the piston against the rod, which in turn moves the mechanical component.

Hydraulic cylinders are used in a wide variety of applications, including construction equipment, agricultural machinery, and manufacturing machinery. They are also used in many different industries, such as automotive, aerospace, and marine.

6. How Does Hydraulic Cylinder Work?

Hydraulic cylinders work by using hydraulic fluid to create a force that can be used to move an object. The fluid is held in a cylinder and is pressurized by a piston. When the piston is pushed, the fluid is forced through a small hole in the piston.

This hole is very small, so the fluid has to move very fast. When it hits the back of the cylinder, it creates a force that is much greater than the force of the piston. This force is what moves the object that the hydraulic cylinder is attached to.

Here’s a video of how hydraulic cylinder works:

7. Hydraulic Cylinder Applications

Hydraulic cylinders are used in a variety of applications. Some of the most common applications include:

Lifting Heavy Loads

Hydraulic cylinders are commonly used in lifting applications. They are often used to lift heavy loads that would be difficult or impossible to lift manually. In many cases, hydraulic cylinders are used in conjunction with other lifting devices, such as cranes or winches.

Adjusting the Position of Loads

Hydraulic cylinders can be used to adjust the position of loads. This is often done in manufacturing or assembly applications. By using hydraulic cylinders, loads can be precisely positioned and then held in place. This allows for more accurate and efficient assembly processes.

Actuating Valves

Hydraulic cylinders can be used to actuate valves. This is common in applications where automated valve control is required, such as in some irrigation systems. Hydraulic cylinders are well-suited for this task because they can generate a large amount of force with relatively little input power.

There are many other potential applications for hydraulic cylinders. These are just a few of the most common uses. With their versatility and high level of performance, hydraulic cylinders can be used in a wide variety of applications.

8. Advantages of Hydraulic Cylinder

There are many advantages that a hydraulic cylinder possesses over other actuation technologies. Here are some of the most notable advantages:

Efficient Power-to-Weight Ratios

A hydraulic cylinder can produce a lot of force while only weighing a fraction of what other technologies weigh. This is due to the fact that hydraulics use fluid pressure to create force, which is a very efficient way to transmit energy.

Variable Speed Control

A hydraulic cylinder can be easily controlled to move at any speed, from very slow to very fast. This is due to the fact that hydraulics are not limited by mechanical gearing like other technologies.

Precise Positioning

Hydraulic cylinders are very precise and can be easily positioned within 0.001 inches. This is due to the fact that hydraulics use fluid pressure to create force, which is a very consistent way to transmit energy.

High Energy Efficiencies

hydraulic cylinder with electric pump is very energy efficient, due to the fact that they use fluid pressure to create force. Fluid pressure is a very efficient way to transmit energy, and it results in minimal energy loss.

Long Service Life

Hydraulic cylinders have a very long service life, due to the fact that they are very reliable and have few moving parts. This means that there are fewer opportunities for something to go wrong and require repairs or replacement.

These are just a few of the many advantages that hydraulic cylinders possess. If you are in need of an actuation solution, be sure to consider a hydraulic cylinder. You may find that it is the perfect option for your needs.

9. The Key Differences Between Electric and Hydraulic Cylinders

When it comes to powering your machinery, there are two main types of cylinders you can choose from: electric and hydraulic. And while both options have their advantages and disadvantages, there are some key differences that you should be aware of before making your final decision.

Here’s a quick rundown of the key differences between electric and hydraulic cylinders:

| Electric Cylinders | Hydraulic Cylinders |

|---|---|

| powered by electricity | powered by fluid pressure |

| use a linear motor to produce linear motion | use fluid pressure to produce linear or rotary motion |

| typically smaller and lighter | often larger and heavier than electric cylinders |

| cost more than hydraulic cylinders because they require a more complex control system | often less expensive because they can be powered by a simple pump |

Power Source

The most obvious difference between electric and hydraulic cylinders is their power source. Electric cylinders are powered by electricity, while hydraulic cylinders are powered by fluid pressure.

Operation

Another key difference between electric and hydraulic cylinders is the way they operate. Electric cylinders typically use a linear motor to produce linear motion, while hydraulic cylinders use fluid pressure to produce linear or rotary motion.

Size and Weight

Electric cylinders are typically smaller and lighter than hydraulic cylinders, making them ideal for applications where space is limited. Hydraulic cylinders, on the other hand, are often larger and heavier than electric cylinders, making them better suited for heavy-duty applications.

Cost

Electric cylinders typically cost more than hydraulic cylinders because they require a more complex control system. Hydraulic cylinders, on the other hand, are often less expensive because they can be powered by a simple pump.

As you can see, there are some key differences between electric and hydraulic cylinders. Understanding these differences will help you choose the right type of cylinder for your application.

If you’re looking for a 12v electric over hydraulic cylinder manufacturer, look no further than Uphyd. We offer a wide variety of electric over hydraulic cylinders that are perfect for a variety of applications. Contact us today to learn more about our products and how we can help you find the perfect solution for your needs.

10. 5 Buying Tips When Choosing Between Electric and Hydraulic Cylinders

When it comes to choosing between electric and hydraulic cylinders, there are a few things you need to take into account to ensure you’re making the best decision for your needs. Here are some tips that will help you make the right decision:

#1 Type of Application

The first thing you need to consider is the type of application the cylinder will be used for. If you need a cylinder for heavy-duty applications, then hydraulic is the way to go. However, if you need a cylinder for lighter-duty applications, then electric might be a better option.

#2 Flow Rate

The next thing you need to consider is the flow rate. Hydraulic cylinders have a higher flow rate than electric cylinders, so they can handle more work in a shorter period of time.

#3 Operating Temperature

Another thing to keep in mind is the operating temperature. Hydraulic cylinders can operate at higher temperatures than electric cylinders, so they’re ideal for applications that require high heat.

#4 Pressure Rating

The last thing you need to consider is the pressure rating. Hydraulic cylinders have a higher pressure rating than electric cylinders, so they can handle more force.

#5 Cost

Of course, the cost is always a factor to consider when making any purchase. 12v electric hydraulic cylinders are typically more expensive than electric cylinders. However, you need to consider the long-term costs of each option before making a decision.

Choosing between electric and hydraulic cylinders is not an easy task. There are a lot of factors that need to be considered before making a decision. However, by keeping these tips in mind, you can be sure that you’re making the best decision for your needs.

If you’re looking for a reputable actuator manufacturer, Uphyd is a great choice, We offer electric telescopic cylinders and battery operated hydraulic cylinders at a very competitive price. For more information, please visit our website or contact us today to learn more.

11. Conclusion

So there you have it- the electric vs hydraulic cylinder debate. Both have their pros and cons, but in the end, it comes down to what will work best for your specific needs. If you’re still unsure which option is right for you, or if you have any other questions about cylinders, please don’t hesitate to contact us at Uphyd. We would be happy to help!