PRODUCT FEATURES

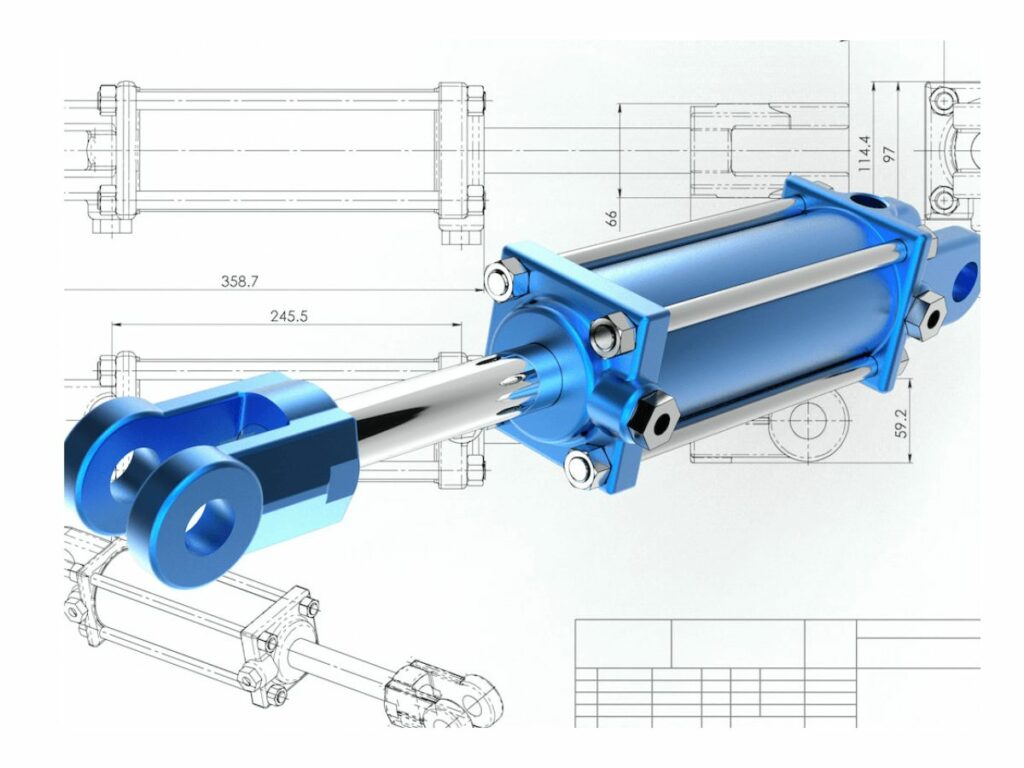

Double Acting Cylinders Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide to Double Acting Cylinders

A double acting cylinder is an essential piece of equipment for any business that relies on hydraulic power. But what are double acting cylinders, and how do they work?

This guide will explain everything you need to know about double acting cylinders, including their advantages and disadvantages. We’ll also provide a comparison between single and double acting cylinders, so you can decide which type is right for your business.

So, if you’re ready to learn more about double acting cylinders, let’s get started!

Table of contents

1. What Are Double Acting Cylinders?

The double acting cylinder is a type of pneumatic or hydraulic cylinder in which compressed fluid is used to push the piston in both directions. This allows for linear actuation in both directions, as opposed to the single acting cylinder, which can only push the piston in one direction.

Double acting cylinders typically have a larger bore than single acting cylinders and can produce more force. They are also more versatile, as they can be used for applications that require linear actuation in both directions.

2. A Quick History

Double acting cylinders have been used for centuries to create a powerful force that can move an object in one or more directions. Though technology has evolved over the years, the general concept remains the same. Here’s a quick look at the history of double acting cylinders.

17th Century

The first double acting cylinders were created in the 17th century by English inventor Thomas Savery. These early cylinders were used to pump water out of mines. The double acting cylinder allowed for a much more powerful force than a single-acting cylinder, making it possible to pump water from greater depths.

18th Century

In the 18th century, double acting cylinders began to be used in steam engines. Scottish engineer James Watt was the first to use double acting cylinder pump in a steam engine. His design was more efficient than earlier designs and quickly became the standard.

19th Century

As double acting cylinders became more common, they were used for a variety of applications. In the 19th century, they were used in locomotives and steamboats. They were also used in pumps, compressors, and other machinery.

Today

Today, double rod hydraulic cylinders are still used in a variety of applications. This includes everything from construction equipment to automotive engines. They are an essential part of many machines and will continue to be used for years to come.

3. How Does It Work?

A double-acting cylinder work by having a port on each end that is connected to a pressure source. As the pressure in one side of the cylinder increases, it causes the piston to move in that direction.

This, in turn, decreases the pressure on the other side of the piston, causing it to move in the opposite direction. The double-acting cylinder can be used to create linear or rotary motion, depending on how it is configured.

Here’s a video to learn more about how does a double-acting cylinder work, take a look at this!

4. Main Components

A double acting cylinder has several key components that work together to produce linear motion. These components include:

Piston

The piston is the central component of the cylinder and contains a seal that separates the two chambers within the cylinder. The piston is connected to the rod, which extends from the cylinder to create linear motion.

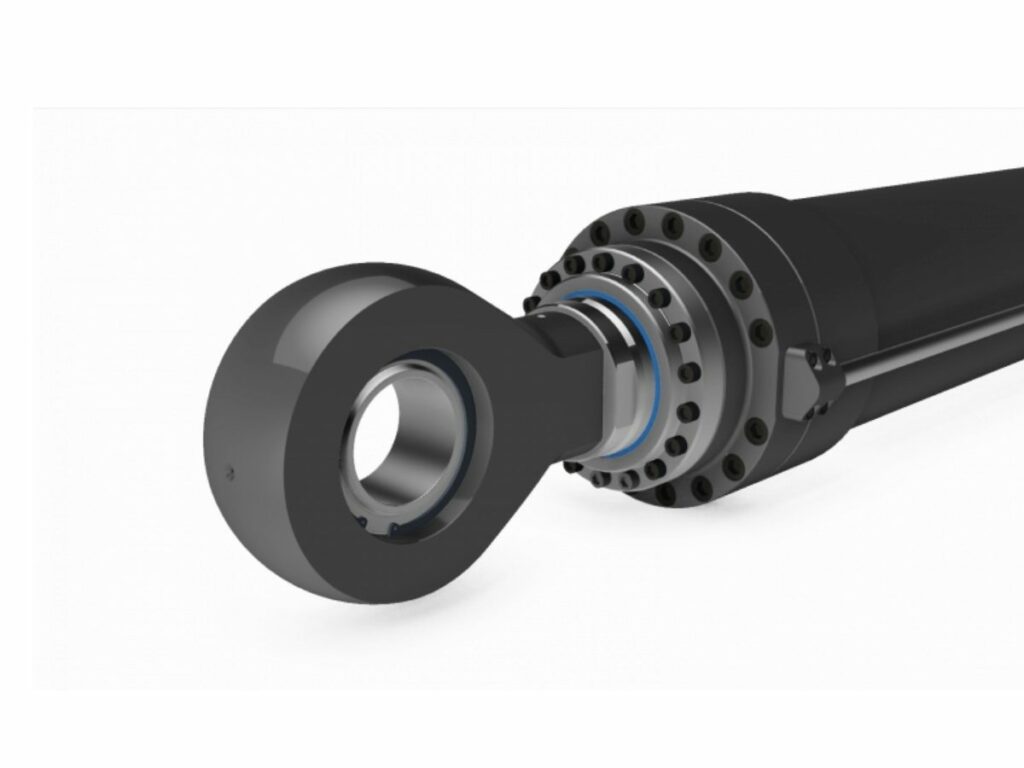

Piston Rod

The piston rod is attached to the piston and extends from the cylinder. The rod is typically made of steel or another strong material that can withstand high temperatures and pressures.

Tie Rod

Tie rods are used to connect the two ends of the cylinder together. They help to support the weight of the piston and rod and prevent the cylinder from moving during operation.

Barrel

The barrel is the pressure-tight cylindrical body of a double acting cylinder. It houses the piston and sealing elements, and provides a means of attachment for the rod(s) or other linear actuator components.

Cap End

The cap end is the closed end of the double acting cylinder. It houses the rod seal and gland and provides a place for mounting the cushions. The cap end also contains the ports that provide air to enter and exit the cylinder.

Rod End

The rod end of a double acting cylinder is the part that connects to the load. It typically has a male thread or a clevis mount. The rod end contains a seal to prevent fluid from leaking out of the cylinder.

These are the main components of a double acting cylinder. Each serves a specific purpose and works together to create linear motion.

5. Key Features and Benefits

There are many features and benefits that dual action hydraulic cylinders offer. Here are some of the key ones:

Higher Force Output

Double acting cylinders can produce double the force of a single acting cylinder of the same size. This is because they use both sides of the piston to generate force, rather than just one.

Faster Actuation

With double acting cylinders, both the extension and retraction phases of the stroke are much faster because the air can flow in either direction. This is due to the double acting cylinders having two ports that allow for air to enter and exit on both sides of the piston.

Reversibility

Because double acting cylinders can act in both directions, they are able to easily change the direction of their force. This makes them very versatile and suitable for a wide range of applications.

Higher Efficiency

Double acting cylinders are more efficient than single acting cylinders because they don’t rely on gravity to return the piston to its original position. Instead, they use the air pressure that is exerted on both sides of the piston.

Smooth Operation

Small double acting hydraulic cylinder provides a smoother operation. This is because the force is applied evenly throughout the stroke, both in the extension and retraction phases.

These are just some of the key features and benefits that double acting cylinders offer. With so many advantages, it’s no wonder they are so popular choice for a wide range of applications.

6. 5 Industrial Application

Double acting cylinders are used in a variety of industries because of the many advantages they offer. Here are a few of the industrial applications where double stroke hydraulic cylinders are used:

#1 Automotive Industry

The automotive industry uses double acting cylinders in car brakes and clutches. The cylinders help to create the pressure needed to engage or disengage the brakes and clutches.

#2 Construction Industry

Construction equipment such as bulldozers and excavators use double acting telescopic cylinders. The cylinders give the equipment the power to push, pull, or lift heavy loads.

#3 Manufacturing Industry

The manufacturing industry uses double acting cylinders in a variety of applications such as conveyor belts, packaging machinery, and assembly lines.

#4 Aerospace Industry

The aerospace industry uses double acting cylinders in aircraft landing gear and door actuators. The cylinders help to control the movement of the landing gear and doors.

#5 Marine Industry

The marine industry uses double acting hollow hydraulic cylinders in boat steering systems. The cylinders help to provide the power needed to turn the steering wheel.

These are just a few of the many industries that use double rod end cylinders. The cylinders offer a variety of advantages that make them ideal for many applications.

7. The Difference Between a Single and Double Acting Cylinder

There are two different types of cylinders: single acting and double acting. There are a few key differences between the 2 types that set them apart. Here are the key differences between them:

| Single Acting Cylinder | Double Acting Cylinder |

|---|---|

| used for light-duty applications | used for more heavy-duty applications |

| have a piston that is only actuated on one side | have a piston that is actuated on both sides |

| produce force in one direction | produce force in both directions |

| can only be retracted by an external force, such as gravity | can be retracted by the internal force of the piston |

| typically less expensive than double acting cylinders | more expensive because they require more parts and are more complex |

#1 Application

Single acting cylinders are typically used for light-duty applications whereas double acting cylinders are used for more heavy-duty applications. This is because double acting cylinders can produce more force than single acting cylinders.

#2 Design

Single acting cylinders have a piston that is only actuated on one side while double acting cylinders have a piston that is actuated on both sides. This means that double acting cylinders have two ports, one for each side of the piston, while single acting cylinders only have one port.

#3 Direction of Force

Single acting cylinders produce force in one direction while double acting cylinders can produce force in both directions. This is because the piston in a double acting cylinder is actuated on both sides, so it can produce force in both directions.

#4 Retraction

Single acting cylinders can only be retracted by an external force, such as gravity, while double acting cylinders can be retracted by the internal force of the piston. This is because double acting cylinders have a port on both sides of the piston, so the piston can act on both sides.

#5 Cost

Single acting cylinders are typically less expensive than double acting cylinders. This is because they are simpler in design and construction. While double acting cylinders can be more expensive because they require more parts and are more complex.

As you can see, there are a few key differences between single and double acting cylinders. When choosing which type of cylinder to use for your application, keep these differences in mind to make sure you choose the right one for your needs.

8. How Much Does It Cost?

The cost of a double acting cylinder can vary depending on the size, material, and other factors. However, on average, a double acting cylinder can cost anywhere from $50 and $200. This makes double acting cylinders a more affordable option than other types of cylinders.

When choosing a long stroke double acting hydraulic cylinder, it is important to consider the intended use and application in order to ensure that you select the most appropriate model for your needs. This will help to ensure that you get the best possible value for your money.

If you’re looking for double acting hydraulic cylinder for sale you can check out our website at Uphyd. We offer a wide variety of double acting cylinders to choose from. You can also contact us if you have any questions about our products or services. Our team would be happy to assist you.

9. 8 Steps on How To Import From Manufacturer

When trying to import from a manufacturer, there are a few key steps that you need to take in order to make sure that the process goes smoothly. Here is the step by step instructions on how to import from a manufacturer:

Step#1 Know Your Needs

The first step is to know exactly what you need from the manufacturer. This includes knowing the quantity, quality, and specifications of the product that you need. Without this information, it will be difficult to find the right manufacturer and get a good deal on the product.

Step#2 Find a Manufacturer

The next step is to find a manufacturer that can provide you with the product that you need. There are several ways to find manufacturers, including online directories, trade shows, and word of mouth. Make sure to research each manufacturer carefully before making a decision to ensure that they are reputable and can provide you with high-quality products.

A great option for a reliable manufacturer is Uphyd. We offer double acting cylinders that are perfect for a variety of needs. Contact us today for more information.

Step#3 Get a Quote

Once you have found a few potential manufacturers, the next step is to get a quote. This will help you compare prices and find the best deal on the product that you need. Make sure to provide the manufacturer with all of the specifications and details of the product so that they can give you an accurate quote.

Step#4 Negotiate the Terms

After you have received a quote from the manufacturer, the next step is to negotiate the terms. This includes the price, payment terms, delivery time, and any other details of the agreement. It is important to have all of the details in writing so that there are no misunderstandings later on.

Step#5 Place Your Order

Once you have negotiated the terms with the manufacturer, the next step is to place your order. Make sure to provide all of the necessary information and specifications so that the manufacturer can produce the product according to your needs.

Step#6 Make the Payment

The next step is to make the payment according to the terms that you have agreed upon. This can be done by wire transfer, credit card, or other methods. Once the payment has been made, the manufacturer will begin production of the product.

Step#7 Track the Order

After the payment has been made, the next step is to track the order. This can be done by contacting the manufacturer or by using an online tracking system. Make sure to keep track of the order so that you can be sure that it is on schedule and will be delivered on time.

Step#8 Receiving the Product

The final step is to receive the product from the manufacturer. Make sure to inspect the product carefully to ensure that it meets your quality standards. If there are any problems with the product, make sure to contact the manufacturer so that they can resolve the issue. If you are satisfied with the product, then you can begin using it in your business.

These are the key steps that you need to take in order to import from a manufacturer. By following these steps, you can be sure that the process will go smoothly and that you will receive the product that you need.

10. 5 Buying Tips To Consider

When looking for double acting cylinders, it is important to consider a few key factors in order to ensure you’re getting the best possible product. Here are some tips to keep in mind:

#1 Material

The material of the double acting cylinder will dictate the overall durability and longevity of the product. The most common materials used for double acting cylinders are aluminum and stainless steel. Make sure to pick a material that will be able to withstand the elements it will be exposed to.

#2 Stroke Length

The first thing you’ll want to consider is the overall stroke length. This will determine how much travel the double acting cylinder can provide. It’s important to choose a length that will suit your needs and application.

#3 Bore Size

The bore size will also be an important factor to consider. This will dictate the overall power and force that the double acting cylinder can provide. Choose a size that is appropriate for your needs.

#4 Mounting Type

There are two main types of double acting cylinders: side mount and bottom mount. Each has its own advantages and disadvantages, so it’s important to choose the type that will best suit your needs.

#5 Pressure Rating

The pressure rating is an important factor to consider when choosing double acting cylinders. This will determine the maximum pressure that the cylinder can withstand. Make sure to choose a pressure rating that is appropriate for your application.

These are just a few of the things you’ll want to keep in mind when choosing double acting cylinders. By taking the time to consider all of your options, you can be sure that you’re getting the best possible product for your needs.

11. Conclusion

That’s it for our ultimate guide to double acting cylinders. We hope you found this information helpful and that it has given you a better understanding of how these cylinders work.

If you have any questions or need assistance with finding the right cylinder for your needs, please don’t hesitate to contact us at UPHYD. We would be happy to help!

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.