PRODUCT FEATURES

Hydraulic Cylinder Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

Hydraulic Cylinder Manufacturer: The Ultimate Guide for Wholesaler

Looking for a hydraulic cylinder manufacturer that can provide you with quality products and excellent customer service? With so many options to choose from, it can be difficult to know where to start.

In this guide, we’ll walk you through everything you need to know about hydraulic cylinders, from how they work to the different types available in the market today. We’ll also provide some tips on what to look for when choosing a hydraulic cylinder manufacturer and a step-by-step guide on how to place an order for import.

So, whether you’re a wholesaler or you just need cylinders for your business, read on to learn more!

Table of contents

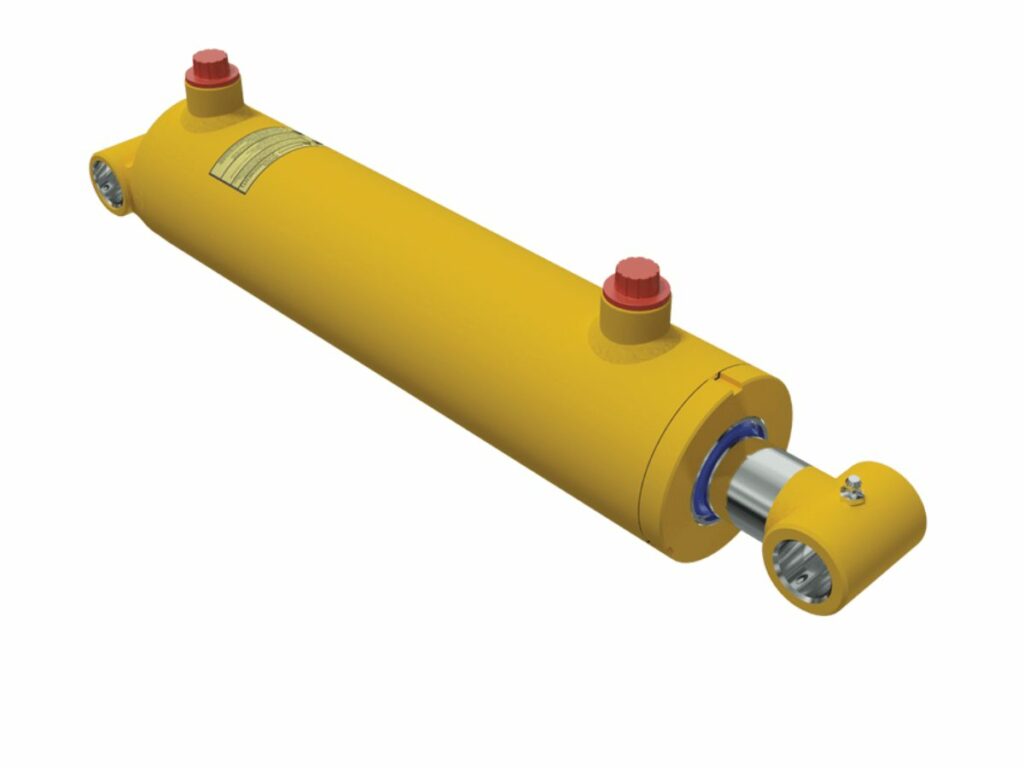

1. What Is Hydraulic Cylinder?

A hydraulic cylinder is a mechanical actuator used to provide linear force and motion, usually in response to hydraulic fluid pressure. Hydraulic cylinders are found in a wide variety of industries and applications. Typically, they are connected to a pump that supplies high-pressure fluid, which then drives the piston in the cylinder.

Hydraulic cylinders are capable of generating very high levels of force, making them ideal for use in construction and industrial settings. They can be made from metals such as steel or aluminum, or they can be made from composites such as fiberglass or carbon fiber.

2. How Does It Work?

A hydraulic cylinder is a device used to convert hydraulic energy into mechanical energy. The cylinder consists of a piston that is free to move up and down within a chamber filled with hydraulic fluid. When the piston is forced downwards, the fluid is forced out of the chamber and into an attached pipe.

This pipe leads to a hydraulic pump, which increases the pressure of the fluid and forces it back into the chamber. As the fluid enters the chamber, it pushes the piston upwards, generating mechanical energy.

3. Key Components and Their Functions

Now that we have a basic understanding of how hydraulic cylinders work, let’s take a closer look at the key components and their functions.

Cylinder Body

The cylinder body houses the piston and rod, and it is typically made from high-strength steel or aluminum. The cylinder body must be strong enough to withstand the pressure of the hydraulic fluid, as well as the force generated by the piston and rod.

Piston

The piston is a disc that is attached to the rod and fits inside the cylinder body. The piston is what creates the pressure inside the cylinder that is used to power the hydraulic system.

Rod

The rod is attached to the piston and extends out of the cylinder body. The rod is what transfers the force from the piston to the hydraulic system.

Seals

Seals are placed between the piston and rod, and between the rod and cylinder body, to prevent hydraulic fluid from leaking out of the system.

Ports

Ports are openings in the cylinder body that allow hydraulic fluid to enter and exit the system. The ports are typically located at either end of the cylinder body, but they can also be located on other sides as well.

4. Main Types of Hydraulic Cylinder

Hydraulic cylinders come in a wide variety of shapes and sizes to suit many different applications. Here are the most common types:

Single-Acting

Single-acting cylinders are the most common type of hydraulic cylinder. They have a piston that is actuated by the hydraulic fluid on one side only. This type of cylinder is used in applications where the load is not too heavy and does not need to be constantly actuated.

Double-Acting

Double-acting cylinders are similar to single-acting cylinders, but they have a piston that is actuated by the hydraulic fluid on both sides. This type of cylinder is commonly used in applications where the load is heavy or needs to be constantly actuated.

Telescopic

Telescopic cylinders are hydraulic cylinders that have multiple stages of pistons that extend and retract to provide a large amount of force. This type of cylinder is used in applications where a very large amount of force is required, such as in construction or mining.

Tie Rod Cylinders

Tie rod cylinders are a type of hydraulic cylinder that has rods that extend from the ends of the piston to the end caps. This type of cylinder is used in applications where space is limited, such as in automotive applications.

Welded Body Cylinders

Welded body cylinders are made from a single piece of steel that has been welded together. This type of cylinder is very strong and can be used in applications where high pressures are required, such as in industrial applications.

Cushioned Cylinders

Cushioned cylinders are hydraulic cylinders that have a cushioning device at either end of the piston to absorb shock and protect the load from damage. This type of cylinder is used in applications where loads need to be protected from impacts, such as in material handling or packaging.

5. 6 Industry Application

Hydraulic cylinders are found in a variety of industries and applications. Here are the most common:

| Construction | often used in construction equipment that is used to lift and move heavy objects |

| Manufacturing | used to operate presses that stamp or forge metal parts |

| Agriculture | used to operate hydraulic pumps that are used to irrigate fields |

| Transportation | used to operate hydraulic door closers on vehicles |

| Marine | used to operate hydraulic pumps that are used to move water from one location to another |

| Military | used in many hydraulic weapons, such as hydraulic guns and hydraulic missile launchers |

#1 Construction

Hydraulic cylinders are used in a variety of construction applications, such as operating excavators, backhoes, and bulldozers. Additionally, hydraulic cylinders are often used in construction equipment that is used to lift and move heavy objects like forklifts.

#2 Manufacturing

Hydraulic cylinders are also used extensively in manufacturing applications. For example, they are often used to operate presses that stamp or forge metal parts. Additionally, hydraulic cylinders are used in many assembly line applications, such as moving and positioning car parts during the assembly process.

#3 Agriculture

Hydraulic cylinders are used in a variety of agricultural applications. For example, they are often used to operate hydraulic pumps that are used to irrigate fields. Additionally, hydraulic cylinders are used in many agricultural machines, such as combines and tractors.

#4 Transportation

They are also typically used in many transportation applications. For example, hydraulic cylinders are used in many hydraulic braking systems. Additionally, custom made hydraulic cylinders are often used to operate hydraulic door closers on vehicles like buses and trains.

#5 Marine

They are hydraulic cylinders used in the maritime industry. Hydraulic cylinders are used in hydraulic steering systems for boats and ships. They are also often used to operate hydraulic pumps that are used to move water from one location to another.

#6 Military

They are also used in a variety of military applications. For example, hydraulic cylinders are used in many hydraulic weapons, such as hydraulic guns and hydraulic missile launchers. Additionally, they are often used in military vehicles, such as tanks and armored vehicles.

6. How to Work With Hydraulic Cylinder Manufacturer

To get top-quality products at a more affordable price, work with hydraulic cylinder manufacturers. They can offer custom built hydraulic cylinders at a lower price since they are the direct source. Here’s how you can work with manufacturers:

Step#1 Find Potential Suppliers

The first step is to find potential hydraulic cylinder suppliers that you can work with. You can start your search by looking online or attending trade shows.

Make a list of hydraulic cylinder manufacturers that you’re interested in working with. Once you have your list, it’s time to start contacting them.

Step#2 Clearly Communicate Your Needs

Before you start working with a manufacturer, take some time to assess your needs and communicate them clearly. What size cylinders do you need? What pressures do they need to withstand? What type of environment will they be used in?

This will help the manufacturers to better understand your needs and offer you products that meet your specific requirements.

Step#3 Ask About the Manufacturing Process

It’s important to know how the cylinders will be made before you purchase them. Ask about the materials that will be used and how the cylinders will be tested for quality. This information can help you ensure that you’re getting a high-quality product.

Step#4 Negotiate Payment Terms

Once you’ve found a hydraulic cylinder manufacturer that you’re happy with, it’s time to negotiate payment terms. Be sure to get everything in writing so that there is no confusion later on.

Step#5 Place Your Order

After you’ve negotiated payment terms, it’s time to place your order. Be sure to get a written confirmation of the order so that you have a record of what was agreed upon.

Step#6 Keep an Open Line of Communication

Once you’ve placed your order, keep an open line of communication with the hydraulic cylinder manufacturer. This will help to ensure that everything goes smoothly and that you’re happy with the end product.

7. Step by Step Guide to Import From Manufacturer

The process of importing from a manufacturer can seem daunting, but it doesn’t have to be. By following these simple steps, you can ensure that your import experience is smooth and successful.

Step#1 Establish a Good Communication

This means that you need to be clear about your needs and expectations, and they need to be able to understand your requirements. Good communication will help to avoid misunderstandings and ensure that both parties are on the same page.

Step#2 Get a Quote and Negotiate Price

Once you have an idea of what you need, it’s time to get a quote from the manufacturer. This will give you an idea of the cost of the goods you want to purchase. It’s important to negotiate the price, as this can often save you money.

Step#3 Place Your Order and Make Payment

After you and the manufacturer agree on a price, it’s time to finalize your order. You will need to pay the manufacturer 50% of the total cost as a downpayment, which is typically done through wire transfer.

Step#4 Obtain Necessary Documentation

To import goods from a manufacturer, you will need to obtain the necessary documentation. These documents will be needed in order to clear customs and take possession of your goods.

The documentation may include the following:

- Commercial invoice

- Packing list

- Bill of lading or airway bill

- Certificate of origin

Step#5 Arrange Shipping

After your goods have been manufactured and are ready to be shipped, you will need to arrange shipping. This can be done through a freight forwarder, which is a company that specializes in shipping goods internationally, or by the manufacturer itself.

Step#6 Pay Custom Duties and Taxes

Once your goods arrive at the port of entry, you will need to pay any customs duties and taxes that are due. These fees are based on the value of the goods as well as their classification. This will also be based on the country of origin and the destination country.

Step#7 Receive Your Goods

After you have paid all duties and taxes, you will be able to take possession of your goods. You will need to sign for them and may be required to present the documentation that was obtained in Step 4.

8. 4 Tips When Sourcing for Manufacturer

Sourcing for a hydraulic cylinder manufacturer can be a daunting task, especially if you are not sure where to start. Here are 4 tips to help you source for the right manufacturer:

#1 Do Your Research

You can start by searching online or asking for recommendations from industry peers. Once you have a list of potential manufacturers, you can then narrow down your options based on factors such as experience, quality of products, and price.

One manufacturer you may consider is Uphyd. We are a custom hydraulic cylinder manufacturer with years of experience in the industry. We offer a wide range of hydraulic cylinders, from small to large, and our products are made from high-quality materials. Contact us today to know more about our products and services!

#2 Cheap is Not Always the Best

It is important to remember that when it comes to custom hydraulic cylinders, you get what you pay for. It is better to invest in a quality product that will last long and perform well, rather than a cheap one that will need to be replaced soon.

#3 Consider the Location

If you need hydraulic cylinders urgently, it is better to choose a manufacturer that is located close to you. This way, you can avoid costly shipping fees and delays. However, if you’re looking to save money on labor costs, manufacturers located in Asia may be a better option.

#4 Consider the Size of the Manufacturer

If you need a more custom hydraulic cylinder, it is better to choose a smaller manufacturer that is willing to work with you to create the perfect product. However, if you need a hydraulic cylinder that is more standard, a larger manufacturer may be a better option as they are likely to have a wider range of products.

9. The Average Cost of Hydraulic Cylinder

Hydraulic cylinders typically cost between $50 and $200. The price depends on the quality of the materials used, the size of the cylinder, and the complexity of the design. Hydraulic cylinders can be customized to meet the specific needs of a customer, which can also increase the overall cost.

Additionally, the cost of hydraulic cylinders may be higher if they are purchased from a specialty retailer. That’s why working with a direct hydraulic cylinder manufacturer is often the best option.

10. 5 Buying Tips About Hydraulic Cylinder

When it comes to hydraulic cylinders, there are a few things you need to keep in mind. Here are 5 tips that will help you make the best purchase:

#1 Application

The first thing you need to consider is the application. What are you going to use the hydraulic cylinder for? There are a variety of hydraulic cylinders on the market, each designed for different purposes. Make sure you select the right hydraulic cylinder for your needs.

#2 Size

Hydraulic cylinders come in a variety of sizes. Again, it’s important to select the right size for your needs. The last thing you want is a hydraulic cylinder that’s too small or too large for your application.

#3 Material

Hydraulic cylinders are made from a variety of materials, including aluminum, steel, and stainless steel. Each material has its own benefits and drawbacks. For example, aluminum is lightweight but not as durable as steel. Stainless steel is more expensive but is also more resistant to corrosion.

#4 Pressure

Hydraulic cylinders are rated for different maximum pressures. Make sure you select a hydraulic cylinder that can handle the pressure you need.

#5 Budget

Finally, you need to consider your budget. hydraulic cylinders can range in price from a few hundred dollars to several thousand dollars. It’s important to find a hydraulic cylinder that fits your budget.

11. Conclusion

Hydraulic cylinders can be used for a variety of applications. They are available in a variety of sizes and materials. Working with a direct manufacturer is often the best way to get the hydraulic cylinder you need at a price you can afford.

At Uphyd, we have a wide selection of hydraulic cylinders for sale, and we can custom-design a hydraulic cylinder to meet your specific needs. If you’re looking for a hydraulic cylinder, we can help. Contact us today to learn more about our products and services.

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.