PRODUCT FEATURES

Hydro Pneumatic Cylinder Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Definitive Guide to Hydro Pneumatic Cylinder

As a business owner, you’re always looking for ways to optimize efficiency and cut costs. One way to do that is by using hydro pneumatic cylinders in your operations. But with so many different types and brands on the market, where do you start?

In this definitive guide, we’ll break down everything you need to know about these versatile devices, from their history and applications to the different types available on the market today. We’ll also provide some tips on how to select the right one for your needs.

So, if you’re ready to learn more about hydro pneumatic cylinders, let’s get started!

Table of contents

1. Hydro Pneumatic Cylinder: What Is It?

A hydro pneumatic cylinder is a type of hydraulic cylinder that uses pressurized fluid to generate force and motion. Hydro pneumatic cylinders are often used in industrial and agricultural applications where a large amount of force is required.

Hydro pneumatic cylinders are usually made from metals such as steel or aluminum. The cylinder body is typically filled with hydraulic fluid, and a piston is used to generate force. A hydro pneumatic cylinder can be either single-acting or double-acting. This refers to the direction in which the piston can move.

Hydro pneumatic cylinders typically have a large bore and a small stroke, which makes them well-suited for applications where space is limited. Hydro pneumatic cylinders are also capable of generating a high amount of force relative to their size.

2. The Features of Hydro Pneumatic Cylinder

There are plenty of features to hydro pneumatic cylinder that makes it an interesting and useful tool. Here are some key features:

| Simple Control Circuits | One of the benefits of hydro pneumatic cylinders is that they can be controlled by simple control circuits. This makes them more versatile and easier to use in a range of applications. |

| No External Reservoir | The hydro pneumatic cylinder uses the water pressure from the mains to operate, meaning that there is no need for an external reservoir. This makes it more compact and easier to install. |

| 3 Major Moving Components | The hydro pneumatic cylinder only has 3 major moving components, as opposed to the 7 in a traditional air-based system. This makes it more reliable and easier to maintain. |

| Total/Air oil Separation on Both Sides of the oil | In a hydro pneumatic cylinder, the oil is totally/air separated on both sides of the piston. This prevents cross-contamination and ensures that the oil stays clean. |

| Linear Output Forces Up to 200 tons | The hydro pneumatic cylinder can generate a linear output of up to 200 tons. This makes it suitable for a wide range of applications. |

| Heavy Duty Construction | The hydro pneumatic cylinder is built for durability and reliability. It is constructed from high-quality materials and designed to withstand heavy use. |

These are just some of the key features of hydro pneumatic cylinders. If you’re looking for a versatile and reliable tool, hydro pneumatic cylinders are a great option.

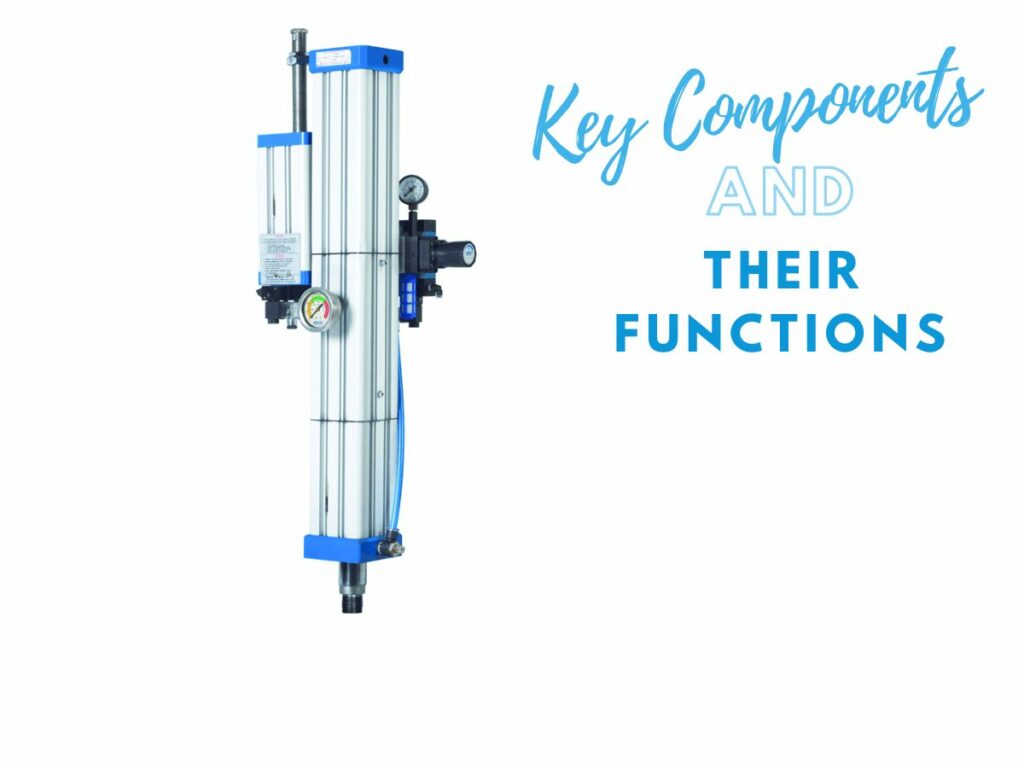

3. Key Components and Their Function

A hydro pneumatic cylinder is made up of several key components, each of which plays an important role in its operation. Here is a look at the most important components and their function within the hydro pneumatic cylinder:

Piston

The piston is the moving part of the hydro pneumatic cylinder that actually creates linear motion. It is sealed at both ends and attaches to the rod, which extends from the cylinder. As hydraulic fluid enters the chamber, it exerts pressure on the piston, causing it to move.

Piston Rod

The piston rod is attached to the piston and extends from the cylinder. It is typically made of steel or another strong material that can withstand high levels of force. The rod transmits the force created by the hydraulic fluid to the load, which is attached to the other end.

Barrel

The barrel is the hollow cylinder that holds the hydraulic fluid. It is typically made of steel, aluminum, or another strong material. The barrel has a threaded end that is used to attach the hydro pneumatic cylinder to a mounting bracket.

Seals

Seals are located at both ends of the hydro pneumatic cylinder to prevent hydraulic fluid from leaking out. They are also responsible for keeping dirt and other contaminants out of the system.

Cylinder Head

The cylinder head seals the top of the cylinder and contains a port that allows hydraulic fluid to enter the cylinder.

Rod End Cap

The rod end cap seals the bottom of the cylinder and contains a port that allows hydraulic fluid to exit the cylinder.

These are the key components of a hydro pneumatic cylinder and their function. Understanding how each component works is essential to understanding how the hydro pneumatic cylinder works as a whole.

4. The Different Types of Hydro Pneumatic Cylinder

There are many different types of hydro pneumatic cylinders, each with its own advantages and disadvantages. Here is a brief overview of the most common types:

Single-Acting Pneumatic Cylinders

Single-acting pneumatic cylinders are the most basic type of hydro pneumatic cylinder. They rely on atmospheric pressure to extend the piston, and spring tension to retract it. This makes them relatively simple and inexpensive, but they can only be used for applications where the load is not too heavy.

Double-Acting Pneumatic Cylinders

Double-acting pneumatic cylinders are more versatile than single-acting cylinders, as they can be used for both push and pull applications. They rely on atmospheric pressure to extend the piston but use compressed air to retract it. This makes them more expensive than single-acting cylinders, but they can be used for much heavier loads.

Telescopic Pneumatic Cylinders

Telescopic pneumatic cylinders are used for applications where a very long stroke is required. They have a number of nested pistons that extend and retract in sequence, allowing them to achieve much longer strokes than other types of hydro pneumatic cylinders. This makes them more expensive than other types of cylinders, but they are essential for some applications.

These are the most common types of hydro pneumatic cylinders. When choosing a hydro pneumatic cylinder, it is important to select one that is appropriate for the task at hand to ensure optimal performance.

5. 5 Industy Application

A hydro pneumatic cylinder is a machine that uses both hydraulic and pneumatic power to create motion. They are often used in industrial applications where precise force and motion are required. Some common industry applications for hydro pneumatic cylinders include:

#1 Automotive

The automotive industry uses hydro pneumatic cylinders for a variety of purposes. They are often used in auto body shops to gently lift and move cars while they are being worked on. Hydro pneumatic cylinders are also used in the assembly of car engines and transmissions.

#2 Electronic

Hydro pneumatic cylinders are commonly used in the electronic manufacturing industry. They are often used to assemble delicate electronic components. Hydro pneumatic cylinders can also be used to test the strength of circuit boards and other electronics.

#3 Appliances

Hydro pneumatic cylinders are used in the manufacture of many appliances. They are often used to assemble the various components of washers, dryers, and dishwashers. Hydro pneumatic cylinders can also be used to test the strength of appliance doors and hinges.

#4 Furniture

Hydro pneumatic cylinders are commonly used in the furniture industry. They are often used to assemble chairs, tables, and dressers. Hydro pneumatic cylinders can also be used to test the strength of furniture joints and frames.

#5 Medical Devices

The hydro pneumatic cylinder is often used in medical devices. It is used in blood pressure monitors, dialysis machines, and X-ray machines. The hydro pneumatic cylinder helps to regulate the pressure in these devices so that they can function properly.

These are only a few of the many industries that use hydro pneumatic cylinders. As you can see, hydro pneumatic cylinders are versatile machines that can be used for a variety of purposes. If you need a machine that can provide precise force and motion, a hydro pneumatic cylinder may be the perfect choice for your needs.

6. The Manufacturing Process

There are several steps involved in the hydro pneumatic cylinder’s manufacturing process, all of which must be carefully executed in order to produce a high-quality product. Here is an overview of the hydro pneumatic cylinder manufacturing process:

Step#1 Design and Development

The first step in the hydro pneumatic cylinder manufacturing process is design and development. In this phase, the hydro pneumatic cylinder’s dimensions, specifications, and other factors are determined. A hydro pneumatic cylinder’s size, for example, will be based on the application it will be used for.

Step#2 Material Selection and Preparation

Once the hydro pneumatic cylinder’s design is finalized, the next step is to select the materials that will be used to construct it. These materials must meet the hydro pneumatic cylinder’s specifications in order to ensure proper function. Once the materials are selected, they must be prepared for assembly.

Step#3 Machining and Welding

The hydro pneumatic cylinder’s parts are then machined and welded together according to the hydro pneumatic cylinder’s design. This step is critical to the hydro pneumatic cylinder’s function and must be done with precision.

Step#4 Collecting and Assembly

The hydro pneumatic cylinder’s parts are then collected and assembled. This step requires attention to detail in order to ensure that all of the hydro pneumatic cylinder’s parts are properly assembled and functioning correctly.

Step#5 Painting and Finishing

The hydro pneumatic cylinder’s final steps are painting and finishing. In this phase, the hydro pneumatic cylinder is given a protective coating of paint and any final touches are applied. This step protects the hydro pneumatic cylinder from the elements and ensures a long lifespan.

Step#6 Testing and Quality Assurance

After the hydro pneumatic cylinder is painted and finished, it undergoes testing and quality assurance. This step ensures that the hydro pneumatic cylinder meets all of the necessary specifications and is free of any defects. Once the hydro pneumatic cylinder passes these tests, it is ready to be used in a variety of applications.

The manufacturing process of hydro pneumatic cylinder is critical to its function and longevity. By following these steps, hydro pneumatic cylinders can be produced that are high in quality and able to withstand the rigors of their intended use.

To learn more of how hydro cylinders are manufactured, check this video!

7. The Average Cost of Hydro Pneumatic Cylinder

The average cost of a hydro pneumatic cylinder can vary depending on the size and specifications of the cylinder. But generally, the average cost of a hydro pneumatic cylinder is between $500 and $1,000.

The cost of a hydro pneumatic cylinder also depends on the manufacturer. Some manufacturers offer discounts for bulk orders, while others charge more for shipping and handling. To get the best deal on a hydro pneumatic cylinder, it’s important to compare prices from multiple suppliers to find the one that offers the best price and value.

If you’re interested in purchasing a pneumatic hydraulic cylinder, you can check out our website at Uphyd. We offer a wide variety of hydro pneumatic cylinders to choose from, all at competitive prices. Contact us today to learn more!

8. How To Work With Hydro Pneumatic Cylinder Manufacturer

When you are ready to purchase a hydro pneumatic cylinder, it is important that you work with a reputable manufacturer to ensure that you are getting a quality product. Here are some tips on how to work with hydro pneumatic cylinder manufacturer:

Know Your Needs

It is important that you know exactly what you need before you start working with a hydro pneumatic cylinder manufacturer. You should have a clear idea of the specifications that you need and the application that the hydro pneumatic cylinder will be used. This will help the manufacturer to provide you with the right product.

Have A Budget In Mind

When you are working with a hydro pneumatic cylinder manufacturer, it is important to have a budget in mind. This will help the manufacturer to provide you with a product that is within your budget.

Ask For Samples

When you are working with a hydro pneumatic cylinder manufacturer, it is important to ask for samples. This will allow you to see the quality of the product and make sure that it is what you need.

Be Flexible

When you are working with a hydro pneumatic cylinder manufacturer, it is important to be flexible. There may be times when the manufacturer needs to make changes to the product in order to meet your needs.

These are just a few tips on how to work with hydro pneumatic cylinder manufacturers. By following these tips, you can be sure that you are getting a quality product that meets your needs.

If you’re looking for a reputable manufacturer, Uphyd is a great choice. We offer a wide range of hydro pneumatic power cylinders, and our team is always available to answer any questions you may have. Contact us today to learn more.

9. 5 Buying Traps To Avoid

When you’re in the market for a hydro pneumatic cylinder, there are a few traps you’ll want to avoid to ensure you’re getting the best possible product for your needs. Here are 5 of the most common traps:

#1 Overlooking the Quality of the Product

When you’re looking at hydro pneumatic cylinders, it’s important to pay attention to the quality of the product. There are a lot of different manufacturers out there, and not all of them are created equal. Make sure you’re getting a cylinder from a reputable manufacturer that uses high-quality materials.

#2 Assuming All Hydro Pneumatic Cylinders Are the Same

Just because 2 hydro pneumatic cylinders look the same, doesn’t mean they are. There can be big differences in quality, performance, and price. Make sure you compare apples to apples when you’re looking at different models.

#3 Not Paying Attention to the Details

The details of a hydro pneumatic cylinder can make a big difference in how well it works. Pay attention to things like the bore size, stroke length, and mounting options. These details can make a big difference in the overall performance of the cylinder.

#4 Buying Bargain Cylinders

Just because a hydro pneumatic cylinder is priced low doesn’t mean it’s a good deal. In fact, many times, the lower-priced options are of inferior quality. This can lead to expensive repairs or even replacement down the road. It’s important to do your research and make sure you’re getting a high-quality product that is built to last.

#5 Buying From the Wrong Supplier

There are a lot of different hydro pneumatic cylinder suppliers out there. It’s important to find one that is reputable and has a good track record. Make sure you read online reviews and ask around to see who others have used. This will help you make the best decision for your needs.

These are just a few of the traps you’ll want to avoid when you’re buying hydro pneumatic cylinders. By taking the time to do your research and choose a quality product, you can ensure that your cylinders will provide years of trouble-free service.

10. Conclusion

So there you have it, the definitive guide to hydro pneumatic cylinders. We hope you found this information helpful and that it has given you a good starting point for your own research into these amazing machines.

If you have any questions or would like more information, please don’t hesitate to contact us at UPHYD. We are always happy to help!

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.