PRODUCT FEATURES

Telescopic Cylinder Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide to Telescopic Cylinder

If you’ve ever used a hydraulic power pack, then you know that Telescopic cylinders are an essential part of the system. But what do you really know about them?

In this guide, we’ll take a closer look at telescopic cylinders and everything they can do for your business. We’ll also discuss the different types of telescopic cylinders and how to choose the right one for your needs.

So whether you’re just starting out or you’re looking to upgrade your current system, read on for all the info you need!

Table of contents

1. Telescopic Cylinder: The Basics

A telescopic cylinder is a type of pneumatic actuator that is used to produce linear motion. It is comprised of a series of nested cylinders, with each one fitting inside the next larger one. When air or fluid pressure is applied to the telescopic cylinder, it extends or contracts to create linear movement.

Telescopic cylinders typically have a bore (inner diameter) ranging from 20 mm to 200 mm. They are available in a variety of strokes (the distance the cylinder can extend), from 50 mm to 5,000 mm.

When air or fluid pressure is applied to the telescopic cylinder, it extends or contracts to create linear movement. The cylinders are telescopic, meaning they can extend and collapse like a telescope.

Telescopic cylinders are often used in applications where space is limited, or when a large amount of linear travel is required from a relatively small amount of force. Telescopic cylinders can be found in a variety of industries, including construction, automotive, and manufacturing.

2. How Does It Work?

Telescoping cylinders work by using hydraulic fluid to actuate a piston that is connected to a telescoping rod. The telescoping rod is able to extend or retract by moving in and out of the cylinder body.

When the telescopic cylinder is extended, the volume of the hydraulic fluid decreases, which causes an increase in pressure. This increase in pressure creates a force on the piston that is transmitted to the telescopic rod, causing it to extend.

The opposite happens when the telescopic cylinder is retracted. The volume of the hydraulic fluid increases, which decreases the pressure. This decrease in pressure creates a force on the piston that is transmitted to the telescopic rod, causing it to retract.

Telescopic cylinders are often used in telescoping boom cranes, dump trucks, and other heavy-duty machinery. They offer a compact design and a long stroke length, making them ideal for many applications.

To know more about how telescopic cylinder works, check this video!

3. Telescopic Cylinder Design

There are several parts of a small telescopic hydraulic cylinder that must be designed in order to function correctly. Here is a list of the parts that must be designed:

- First Piston

- Second Piston

- Third Piston

- Barrel

- First Stage

- Second Stage

- Third Stage/Rod

- First Gland

- Second Gland

- Third Gland

- Rod Eye

- End Cap

- Barrel Lug

These parts work together to create the telescopic cylinder. Each part has a specific function that must be taken into account when designing the telescopic cylinder.

4. Types of Telescopic Cylinders

Telescopic cylinders come in a variety of shapes and sizes, each with its own unique benefits. Here are some of the most common types of telescopic cylinders:

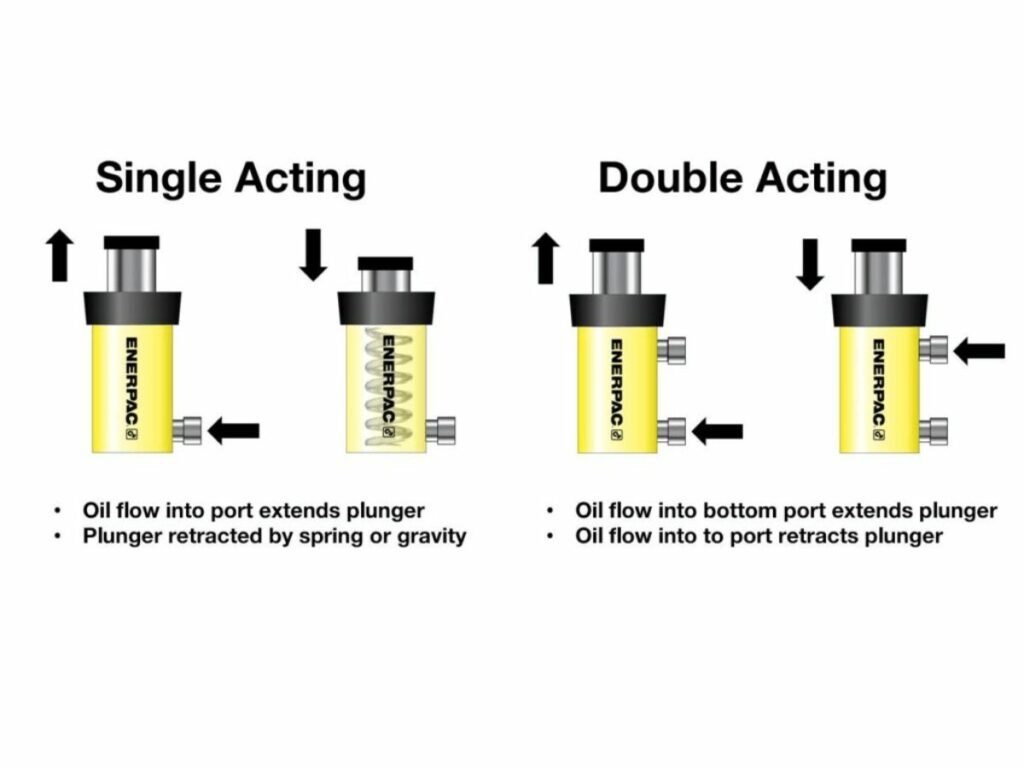

Single Acting Telescopic Cylinders

Single-acting telescopic cylinders are the most basic type of telescopic cylinder. It is extended using hydraulic or pneumatic pressure but is retracted using external force. This type of telescopic cylinder is typically used from a load that is always present such as a dump truck.

Double Acting Telescopic Cylinders

Double-acting telescopic cylinders can be extended and retracted using hydraulic or pneumatic pressure, making them more versatile than a single-acting telescopic cylinder. This type of telescopic double acting cylinder is typically used in applications where load conditions may vary such as garbage compactors, excavator shovels, and roll-on/off trucks.

Single/Double Acting Combination

Single/double-acting telescopic cylinders are typically used when retract force is only required during certain conditions. An example of this is the mast raising cylinder on a drilling rig, which is only required to retract when the mast needs to be lowered.

These are the most common types of telescopic cylinders. When choosing a telescopic cylinder, it is important to consider the specific needs of your application to ensure that you select the best type of telescopic cylinder for the job.

5. 5 Industrial Application

Telescopic cylinders are commonly used in a wide variety of industries because of their unique abilities to extend and retract. Here are some of the most common industry applications where dual stage hydraulic cylinder is used:

#1 Agriculture

Telescopic cylinders are often used in agricultural machinery, such as combine harvesters, tractors, and loaders. They help to extend the reach of the machinery, making it easier to harvest crops and transport them.

#2 Construction

Telescopic cylinders are also used in construction equipment, such as telescopic handlers, cranes, and excavators. By extending and retracting, they enable the machinery to reach high places and tight spaces.

#3 Mining

Telescopic ram cylinders are used in mining equipment, such as rock breakers and drill rigs. They enable the machinery to reach tight spaces and break through hard materials.

#4 Transportation

telescopic cylinders are used in a variety of transportation applications, such as in loading docks, garbage trucks, and buses. They help to extend the reach of the machinery, making it easier to load and unload cargo.

#5 Manufacturing

Multi stage hydraulic cylinders are used in a variety of manufacturing applications, such as in assembly lines and conveyors system. They help to extend and retract the machinery, making it easier to move materials around.

These are just a few of the many industries where multi stage double acting hydraulic cylinders are used. Their unique ability to extend and retract makes them an essential part of many different types of machinery.

6. Telescopic vs Standard Cylinder: What’s the Difference?

Telescopic cylinders and standard cylinders are both types of pneumatic cylinders, which use pressurized air to generate linear force and motion. However, there are some key differences between these 2 types of cylinders that you should be aware of. Here’s a quick rundown of the main telescopic vs standard cylinder differences:

| Stroke Length | Telescopic cylinders have a much longer stroke length than standard cylinders. This is because telescopic cylinders have multiple stages (usually 3 or 4), each of which extends to create a longer overall stroke length. In contrast, standard cylinders only have 1 stage, so they can only extend to a certain point. |

| Force | Due to their long stroke length, telescopic cylinders can generate more force than standard cylinders. This is because the telescopic cylinder’s additional stages give it a larger surface area, which allows it to exert more force. |

| Weight | Telescopic cylinders are also generally much heavier than standard cylinders. This is due to the fact that telescopic cylinders have more parts (i.e. multiple stages), which makes them heavier overall. |

| Cost | Telescopic cylinders tend to be more expensive than standard cylinders. This is because they are generally more complex and require more parts, which raises the cost of production. |

| Applications | Telescopic cylinders are typically used in applications where a long stroke length is required, such as in dump trucks or telescoping boom cranes. Standard cylinders, on the other hand, are better suited for applications where a shorter stroke length is sufficient, such as in pneumatic actuators. |

As you can see, there are some key differences between telescopic cylinders and standard cylinders. It’s important to choose the right type of cylinder for your specific application in order to ensure optimal performance.

7. How Much Does It Cost?

The cost of the telescopic cylinder will vary depending on the manufacturer, the size and type of the cylinder, and the specific application for which it will be used. Telescopic cylinders can range in price from $100 to $1,000 or more.

When choosing a telescopic cylinder, it is also important to consider the specific application for which it will be used. This will help to ensure that the cylinder is able to withstand the conditions it will be exposed to.

When shopping for a telescoping cylinder hydraulic, it is important to compare prices and features from different manufacturers to find the best deal. There are many telescopic cylinders on the market, so it is important to do some research to find the right one for your needs.

If you’re interested in purchasing a telescopic hydraulic cylinder for sale, then be sure to check out our selection at Uphyd. We offer a wide variety of telescopic cylinders to choose from, so you’re sure to find the perfect one for your needs. Contact us today to learn more.

8. 8 Steps on How To Import From Manufacturer

Manufacturers usually have their own procedures for importing goods into a new country. It is important to be aware of these procedures in order to avoid any delays or problems with your telescopic cylinders. The following steps will help you to import telescopic cylinders from a manufacturer successfully:

Step#1 Know Your Needs

The first step is to assess your needs and figure out exactly what telescopic cylinders you need to import. This will determine how much money you need to spend on the project and also help you to find the right supplier.

Step#2 Research Suppliers

Once you know what telescoping hydraulic cylinder you need, you can start researching suppliers. Look for manufacturers who have experience in exporting to your country and who offer competitive prices.

A great option for reputable suppliers is Uphyd. We offer a wide range of telescopic cylinders to suit your needs and budget. Contact us today for more information.

Step#3 Get Quotes

Once you have shortlisted a few suppliers, get quotes from them. This will help you to compare prices and choose the best deal.

Step#4 Negotiate

Once you have decided on a supplier, it is time to negotiate the terms of the deal. This includes the price, delivery date, and any other conditions that need to be met.

Step#5 Place Your Order

After the negotiation is complete, you can place your order with the chosen supplier. Make sure that all the details of the deal are clearly mentioned in the contract so that there are no problems later on.

Step#6 Make the Payment

Once the order is placed, you will need to make the payment to the supplier. This can be done through a variety of methods, including bank transfer, credit card, or PayPal. Make sure that you get a receipt for the payment so that you have proof of purchase.

Step#7 Track Your Shipment

Once the payment is made, the supplier will arrange for the telescopic cylinders to be shipped to your country. You can track the shipment online so that you know when it will arrive.

Step#8 Receive Your Product

Once the shipment arrives, check the telescopic cylinders to make sure that they are of good quality. If there are any problems, you can contact the supplier and ask for a replacement or refund. If you are satisfied with the quality, you can start using telescopic cylinders for your business.

Importing telescopic cylinders from a manufacturer can be a daunting task, but if you follow these steps, it will be much easier. With a little research and preparation, you can get the telescopic cylinders you need at a great price.

9. 6 Buying Tips To Consider

When buying a telescopic cylinder, it is important to consider a few factors in order to make sure you are getting the best product for your needs. Here are a few buying tips to keep in mind:

#1 Cylinder Type

The first thing to consider is the type of telescopic cylinder you need. The cylinder type will determine the amount of pressure that the cylinder can withstand. There are 3 main types of telescopic cylinders:

- Single Acting Telescopic Cylinders

- Double Acting Telescopic Cylinders

- Single/Double Acting Combination

Make sure you choose the right type of telescopic cylinder for your application.

#2 Stroke Length

The next thing to consider is the stroke length. For a telescopic cylinder, the stroke length is the maximum distance that the piston can travel from top to bottom. This is important to consider because you need to make sure that the stroke length is long enough to allow for full extension of the telescopic cylinder.

#3 Bore Size

The bore size is another important factor to consider. This is the internal diameter of the telescopic cylinder. The bore size will determine the amount of force that the telescopic cylinder can generate. The bore size is usually 40mm to 800mm.

#4 Rod Diameter

The rod diameter is another factor to consider. This is the diameter of the rod that attaches to the piston. The rod diameter will determine the maximum load that the telescopic cylinder can support. The rod diameter can range from 0.5” to 2 inches.

#5 Operating Pressure

The operating pressure is the maximum pressure that the telescopic cylinder can withstand. This is an important factor to consider because you need to make sure that the telescopic cylinder can handle the pressure of your application. The operating pressure of a telescopic cylinder is typically between 2000 and 3000 psi.

#6 Stages

The number of stages is the final factor to consider. The number of stages refers to the number of telescopic sections that the cylinder has. The more stages, the longer the telescopic cylinder will be able to extend. The stages of the telescopic cylinder are:

- 2 stage telescopic hydraulic cylinder

- 3 stage telescopic hydraulic cylinder

- 4 stage telescopic hydraulic cylinder

- 5 stage telescopic hydraulic cylinder

Make sure to choose the telescopic cylinder with the right number of stages for your need to ensure optimal performance.

These are the main factors to consider when buying a telescopic cylinder. Keep these tips in mind to make sure you choose the best telescopic cylinder for your needs.

10. Conclusion

Telescopic cylinders are a great way to add more functionality to your machines. By understanding the different types of telescopic cylinders and how they work, you can select the right one for your needs.

At UPHYD, we’re experts in hydraulics, so don’t hesitate to contact us if you have any questions or need help selecting the perfect telescopic cylinder for your machine.

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.