PRODUCT FEATURES

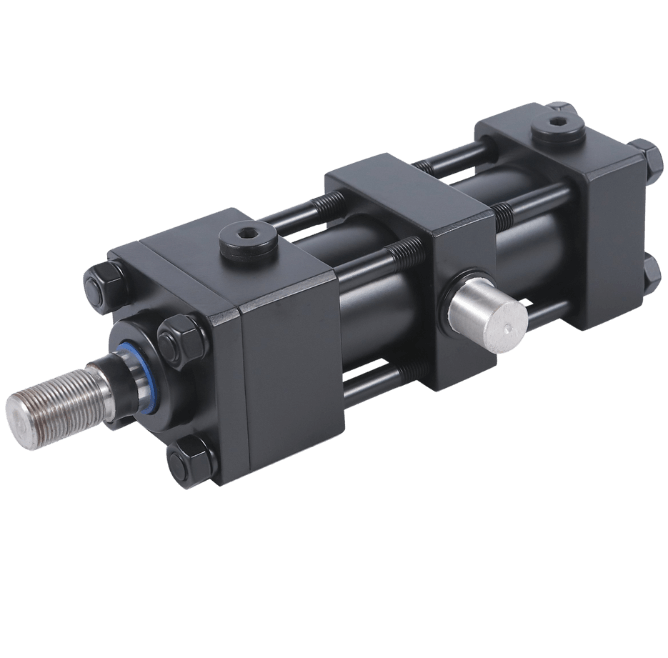

Trunnion Mounted Cylinder Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide to Trunnion Mounted Cylinder

If you use trunnion-mounted cylinders in your business, then you know how important they are for a variety of tasks. From moving heavy loads to providing precise control in manufacturing applications, these cylinders play a vital role. But what do you really know about them?

In this ultimate guide, we’ll explore everything there is to know about trunnion-mounted cylinders, from how they work to the different types available on the market. We’ll also provide some tips on choosing the right cylinder for your needs and the steps to take when importing them from a manufacturer.

So, if you’re ready to learn more about trunnion-mounted cylinders, then let’s get started!

Table of contents

1. What Is Trunnion Mounted Cylinder?

Trunnion-mounted cylinders are heavy-duty pivoting cylinders with pintles attached to the head, cap, or intermediate position. This allows for more stability and higher pressure than a traditional rod-end cylinder. The result is a smoother, more powerful operation that can be used for a variety of applications.

The trunnion mounted telescopic cylinder is supported on both ends, rather than just one. This added support helps to keep the barrel from wobbling or bending under high pressure, which can cause problems with seals and other components. These cylinders are often used in applications where precision and power are essential.

Here’s a video of how trunnion mounted cylinders are made, check this out!

2. How Does It Work?

A trunnion-mounted cylinder is a type of hydraulic cylinder that uses two pivot points to create linear motion. The piston is mounted on a trunnion, which rests in a bearing and allows the piston to rotate. This rotation creates the linear motion needed to power hydraulic machinery.

The basic operation of a trunnion-mounted cylinder is similar to that of any other hydraulic cylinder. The piston rod is attached to the piston, which moves in and out of the barrel as pressurized fluid is admitted or released from the chamber.

The difference lies in how the barrel is mounted: on a fixed mount, it would be bolted or welded in place; on a trunnion mount, it can pivot around the mounting pin, allowing for greater flexibility in alignment with the load vector.

3. Main Components

A trunnion-mounted cylinder has 6 main parts. Let’s go over them one by one.

Cylinder Body

The cylinder body is the longest part of the trunnion-mounted cylinder. It’s where the piston and other components are housed. The cylinder body typically has a diameter of 2 to 12 inches.

Rod

The rod is the part of the trunnion-mounted cylinder that connects the piston to the trunnion. It is usually made of high-strength steel to withstand the high pressures of hydraulic fluid.

Piston

This part of the cylinder is what actually moves the load. The piston is connected to the rod, and it has a seal that prevents fluid from leaking out of the cylinder.

Trunnion

The trunnion is the part of the trunnion-mounted cylinder that allows it to rotate. It’s a round, cylindrical piece that’s attached to the base of the cylinder.

Base

The base is the part of a trunnion-mounted cylinder that sits on an open surface. It’s typically 6 inches in diameter and made with durable material to support heavy tools or machinery.

End Caps

The end caps are the parts of the trunnion hydraulic cylinder that seal the ends of the cylinder body. They prevent fluid from leaking out and keep debris from getting inside the cylinder.

4. Key Features and Benefits

When it comes to choosing the right hydraulic cylinder for your particular application, it is important to consider all of the features and benefits that each type of cylinder has to offer. Here are the most important features and benefits of trunnion mounted cylinder that you should keep in mind:

| High-Degree in Side Load Protection | Thanks to the fact that the trunnion is mounted on the side of the cylinder, rather than on the top or bottom. This gives the cylinder added stability and helps to protect it from damage caused by side loads. |

| Improved Rod Sealing | The side-mounting of the trunnion also helps to improve the sealing around the rod, which in turn helps to prevent leaks and extends the life of the cylinder. |

| Compact Design | Trunnion mounted hydraulic cylinders are typically smaller and more compact than other types of cylinders, making them ideal for applications where space is limited. |

| Simplified Mounting Options | Trunnion cylinders are the perfect choice for those looking to mount their cylinder quickly and easily. They only require two mounting points, which makes it easy when compared with other types of systems that often require four or more screws into different surfaces to get them mounted properly. |

5. 5 Industrial Application

Trunnion-mounted cylinders are heavy-duty cylinders that are commonly used in industrial applications. Here are 5 common industrial applications for trunnion-mounted cylinders:

#1 Manufacturing

Trunnion-mounted cylinders are often used in manufacturing applications because of their high level of strength and durability. They can be used to lift heavy objects or to apply pressure to materials during the manufacturing process.

#2 Automotive

They can be used to lift heavy objects, such as engines, or to apply pressure to materials during the assembly process. They are usually found in car assembly plants.

#3 Construction

They can be used to lift heavy objects, such as beams, or to apply pressure to materials during the construction process.

#4 Mining

They can be used to lift heavy objects, such as ore, or to apply pressure to materials during the mining process. They are also used to move large pieces of equipment.

#5 Oil and gas

Trunnion-mounted cylinders are also commonly used in the oil and gas industry. They can be used to lift heavy objects, such as pipes, or to apply pressure to materials during the drilling process.

6. How Much Does It Cost?

A trunnion-mounted cylinder typically costs between $100 and $300. This cost may still vary depending on a number of factors. For one, the materials used in the construction of the cylinder can affect its overall cost.

Second, the size and capacity of the cylinder will also play a role in how much it costs. Lastly, the brand name associated with the product can also dictate its price point.

7. 6 Steps on How to Import From Manufacturer

This part will show you how to import trunnion-mounted cylinders from a manufacturer in 6 easy steps.

Step#1 Find a Reputable Manufacturer

The first step is to find a reputable manufacturer that can provide you with high-quality trunnion-mounted cylinders. You can ask for referrals from friends or business partners who have imported similar products before. Once you have a list of potential manufacturers, you can then proceed to the next step.

One manufacturer you can check out is Uphyd. We are a leading manufacturer of pneumatic and hydraulic equipment. We have been in business for years and have built a reputation for providing high-quality products and excellent customer service.

Step#2 Request for Quotation

After that, you’ll need to ask for quotations from several manufacturers. In your request, state the cylinders’ requirements. This includes the material, size, weight, and other important attributes.

Step#3 Select a Manufacturer and Negotiate Terms

Once you have selected a manufacturer that fits your budget and requirements, you will then need to negotiate the terms of the deal. This includes the price, payment method, delivery date, and other important details.

Step#4 Place Your Order

After the negotiation, you can then proceed to place your order with the manufacturer. Make sure that all the details of the order are clear to avoid any misunderstanding.

The manufacturer will have to ask you to pay a deposit of 50% downpayment before they start working on your order. The remaining 50% will be paid upon delivery.

Step#5 Arrange Shipping

The next step is to arrange to ship the trunnion-mounted cylinders. You can either use air freight or sea freight, depending on your budget and preference. This will only be applicable if the manufacturer is located overseas.

Step#6 Pay Necessary Charges

Before you can receive the trunnion-mounted cylinders, you will need to pay the applicable charges including import duties and taxes. These fees will be paid to the respective authorities before you can take possession of the cylinders.

8. 5 Buying Tips to Consider

When it comes to choosing the right trunnion-mounted cylinder for your needs, there are a few key factors that you’ll need to take into account. Here are 5 of the most important things to keep in mind when making your purchase:

#1 Bore Size

The bore size of the cylinder you choose will have a direct impact on the overall force output. In general, the larger the bore, the higher the force output. If you’re looking for a powerful trunnion-mounted cylinder, then you’ll want to choose one with large bore size. Bore sizes range from 40mm up to 200mm.

#2 Configuration

Trunnion-mounted cylinders come in a variety of different configurations. The most common are single-acting and double-acting. Single-acting cylinders only generate force in one direction, while double-acting cylinders generate force in both directions. If you need a powerful cylinder that can generate force in both directions, then you’ll want to choose a double-acting cylinder.

#3 Rod Diameter

The rod diameter of the cylinder you choose will also have an impact on the overall force output. In general, the larger the rod diameter, the higher the force output. Rod diameters typically range from 12mm up to 60mm.

#4 Pressure Rating

Trunnion-mounted cylinders are available in a variety of different pressure ratings, ranging from 145 PSI up to 3000 PSI. The pressure rating you choose will depend on the specific application you’ll be using the cylinder for. If you’re not sure which pressure rating to choose, it’s always best to err on the side of caution and choose a higher pressure rating than what you think you’ll need.

#5 Stroke Range

The stroke range of the cylinder you choose will also have an impact on the overall force output. In general, the longer the stroke, the higher the force output. Stroke ranges typically range from 50mm up to 1000mm.

9. Conclusion

When sourcing for top-quality trunnion-mounted cylinders, always consider working with a manufacturer with extensive experience and expertise in the field. Also, be sure to take into account the factors mentioned above to ensure that you choose the right cylinder for your needs.

At Uphyd, we have a team of highly experienced engineers who can custom-design and manufacture trunnion-mounted cylinders to meet your specific requirements. Contact us today to learn more about our products and services.

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.