PRODUCT FEATURES

Hydraulic Vane Pump Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide to Hydraulic Vane Pump

If you are in the business of hydraulic equipment, you would have come across the term hydraulic vane pump. It is a type of positive displacement pump that uses vanes to move fluids. The hydraulic vane pump has been in use for a long time and continues to be one of the most popular pumps due to its simple design and ease of operation.

In this guide, we will take you through everything you need to know about hydraulic vane pumps – how they work, their key features, types, applications, and tips on how to buy the best one for your needs.

So, without further ado, let’s jump right in!

Table of contents

1. What Is Hydraulic Vane Pump?

A hydraulic vane pump is a device used to convert hydraulic energy into mechanical energy. It does this by using pistons or vanes to move hydraulic fluid in and out of a cylinder. This type of pump is often used in high-pressure applications, such as hydraulic systems in construction equipment or aircraft.

Hydraulic vane pumps are often used in high-pressure applications, such as hydraulic systems in construction equipment or aircraft. These pumps can be very effective at converting hydraulic energy into mechanical energy, making them a popular choice for many hydraulic systems.

2. How Do Hydraulic Vane Pumps Work?

Hydraulic vane pumps work by using hydraulic fluid to move a piston within a cylinder. The hydraulic fluid is forced into the pump by a hydraulic motor, which is typically powered by an electric motor. The hydraulic fluid then enters the pump chamber through an inlet port and pushes against a series of vanes that are mounted on a rotor.

As the hydraulic fluid pushes against the vanes, the rotor is forced to turn. This action creates hydraulic pressure within the pump chamber, which is used to drive the hydraulic motor that powers the pump.

The hydraulic fluid is then forced out of the pump chamber through an outlet port and into the hydraulic system that the pump is powering. The hydraulic fluid then flows back to the hydraulic vane pump through the return line, completing the cycle.

Check this video to learn more about vane pumps!

3. Key Features

A hydraulic vane pump is a type of hydraulic pump that uses a set of rotating vanes to move hydraulic fluid through the system. This type of pump is often used in industrial applications where high pressure and flow rates are required. Some of the key features of a hydraulic vane pump include:

Versatility

Hydraulic vane pumps can be used for a variety of applications, including hydraulic power generation, hydraulic motor control, and hydraulic fluid transfer.

Maintenance

One of the benefits of a double vane pump is that it is relatively easy to maintain. The hydraulic fluid can be drained and refilled without having to remove the pump from the system, and the vanes can be replaced without having to disassemble the pump. This makes it a good choice for applications where downtime is not an option.

Running Volume

Hydraulic vane pumps have a relatively small running volume, which means that they are not as likely to cause hydraulic fluid cavitation. This makes them a good choice for applications where hydraulic fluid quality is a concern.

Reliability

Hydraulic vane pumps are known for their reliability and durability. They are often used in demanding applications where hydraulic pump failure is not an option.

All in all, hydraulic vane pumps offer a number of advantages over other types of hydraulic pumps. If you are in the market for a hydraulic pump, a vane pump is definitely worth considering.

4. 3 Types of Vane Pumps and Their Function

There are mainly 3 types of hydraulic vane pumps. Let’s take a look at each of them in more detail.

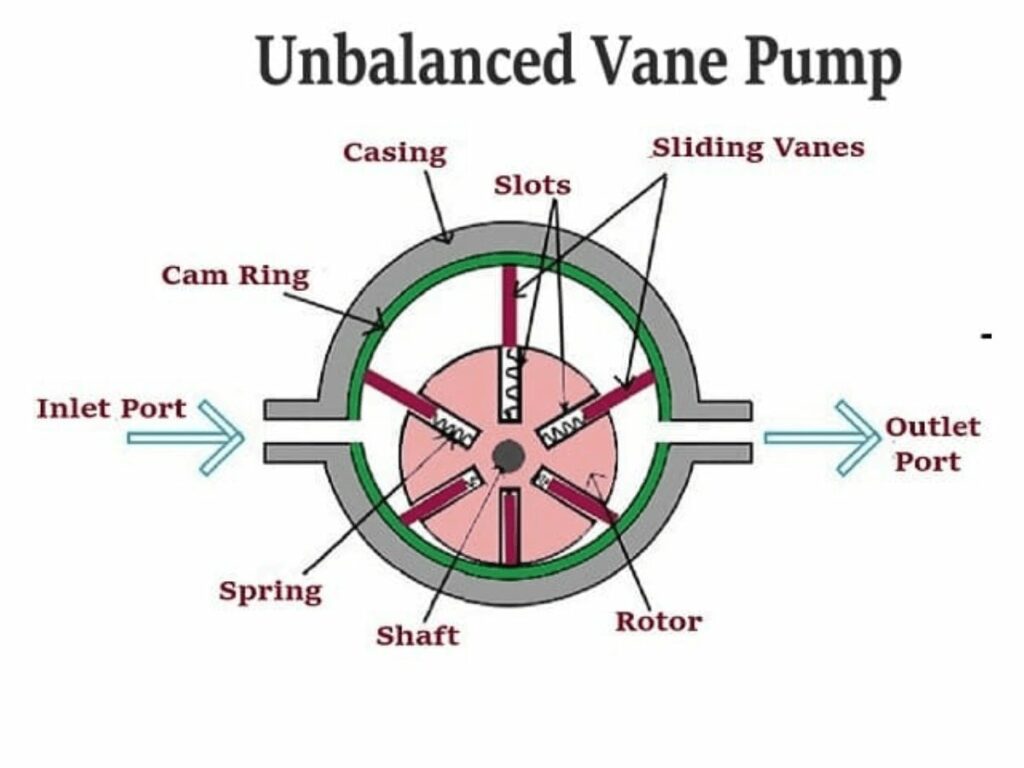

#1 Unbalanced Vane Pumps

Unbalanced vane pumps are the most common type of single-stage vane pump. They are simple and rugged and can handle a wide range of applications. However, they are not very efficient, and can only generate a relatively low amount of pressure.

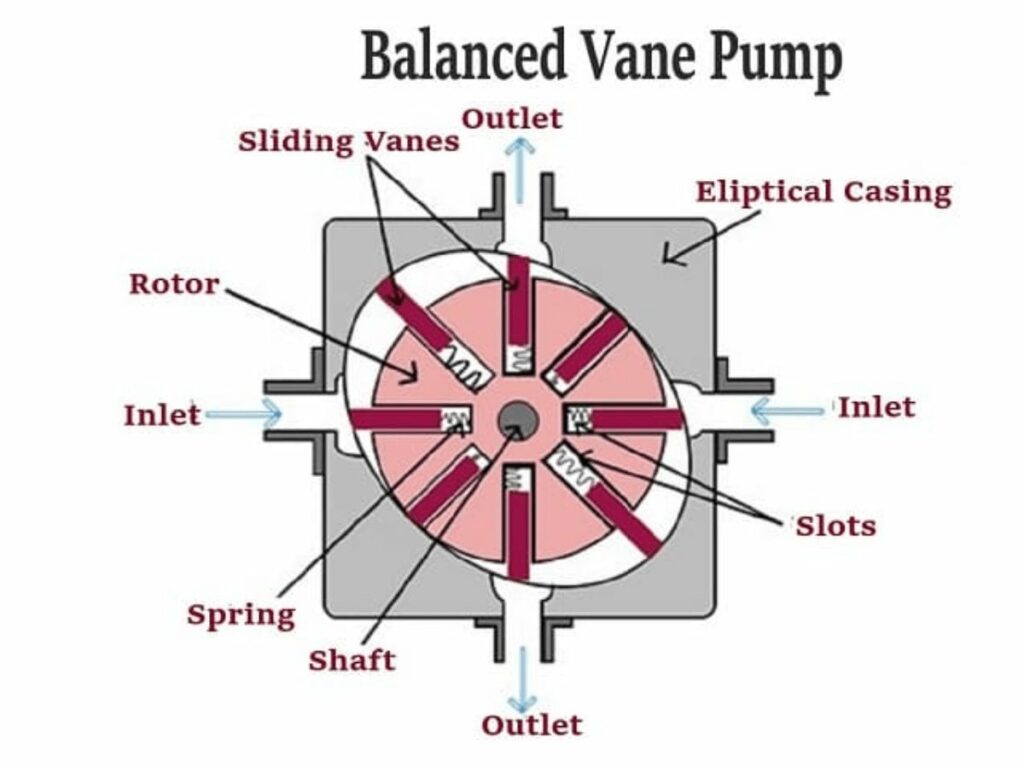

#2 Balanced Vane Pumps

Balanced vane pumps are a more efficient type of single-stage vane pump. They can generate higher pressures than unbalanced vane pumps, but are more expensive and require more maintenance.

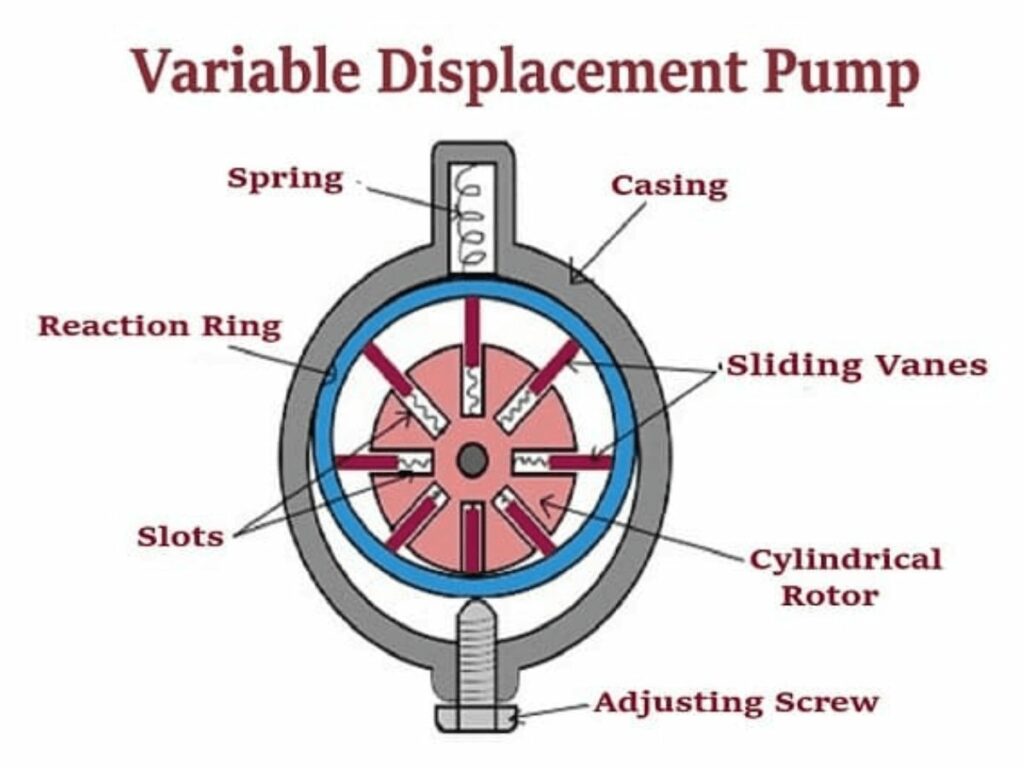

#3 Variable Displacement Vane Pumps

Variable displacement vane pumps are the most efficient type of single-stage vane pump. They can generate high pressures and are very efficient. However, they are expensive and require more maintenance.

Hydraulic vane pumps are a great choice for a wide range of applications. They are simple, rugged, and efficient. However, they do require some maintenance. If you are looking for a pump that can handle a wide range of applications, then a variable vane pump is a great option.

5. The Differences Between Gear, Piston, and Vane Pumps

There are several types of hydraulic pumps available on the market, but the most common are gear, piston, and vane pumps. Each type of pump has its own unique benefits and drawbacks, so it’s important to understand the differences between them before you make a purchase.

Let’s compare their differences in detail:

| Gear Pumps | Piston Pumps | Vane Pumps |

|---|---|---|

| Pump two or more fluids simultaneously | Can be used for a variety of applications, from light-duty to heavy-duty | Ideal for use in high-pressure applications |

| Handle higher pressures than other types of hydraulic pumps | Typically used in industrial and construction settings | Can be used with hydraulic fluids that are highly viscous |

| Quiet operation | Offer a wide range of flow rates | Operation is relatively quiet |

| Typically used in heavy-duty applications | Require less maintenance than other types of hydraulic pumps |

So, which hydraulic pump is right for you? It all depends on your business’s specific needs. No matter which type of hydraulic pump you choose, you can be sure that it will provide the power and performance you need to get the job done right.

6. 7 Industry Application

Industry applications for hydraulic vane pumps are varied and include the following:

#1 Agriculture

Agriculture is one of the most important applications for hydraulic vane pumps. Farmers rely on balanced vane pumps to power irrigation systems, feed and crop processors, and other equipment. Hydraulic vane pumps are essential for maintaining a productive agricultural operation.

#2 Construction

Construction projects often require the use of hydraulic vane pumps to power hydraulic tools and machinery. Hydraulic vane pumps are used to operate excavators, bulldozers, and other heavy equipment.

#3 Mining

Mining operations rely on pressure compensated vane pumps to power hydraulic equipment such as drills, conveyors, and hydraulic lifts. Hydraulic vane pumps are essential for maintaining a safe and productive mining operation.

#4 Manufacturing

Manufacturing facilities use hydraulic vane pumps to power hydraulic presses, injection molding machines, and other hydraulic equipment. Hydraulic vane pumps are essential for maintaining a productive manufacturing operation.

#5 Transportation

Transportation applications for hydraulic vane pumps include powering hydraulic brakes, steering systems, and doors on trains and buses. Hydraulic vane pumps are essential for maintaining a safe and efficient transportation system.

#6 Oil and Gas

The oil and gas industry uses hydraulic vane pumps to power hydraulic fracturing equipment. Hydraulic vane pumps are essential for extracting oil and gas from the ground.

#7 Pharmaceuticals

Pharmaceutical manufacturing facilities use hydraulic vane pumps to power hydraulic tablet presses and capsule fillers. Hydraulic vane pumps are essential for producing safe and effective pharmaceutical products.

These are just a few of the many industrial applications for hydraulic vane pumps. Hydraulic vane pumps are an essential part of many industries and play a vital role in powering hydraulic equipment.

7. The Manufacturing Process

Manufacturing hydraulic vane pumps require a high degree of precision and accuracy. That’s why the manufacturing process is often done using specialized machines and equipment. Here’s the typical manufacturing process for hydraulic vane pumps:

Step #1 Create The Pump Housing

The pump housing is the main body of the pump where all the internal components are housed. It’s typically made from cast iron or steel. The first step in manufacturing the housing is to create a mold.

Step #2 Cut The Pump Housing To Size

Once the housing has cooled and hardened, it’s then cut to size using a CNC machine. It’s important that the housing is cut to precise dimensions so that it can properly house the internal components.

Step #3 Drill Holes In The Pump Housing

The next step is to drill holes in the housing for the various internal components. This is typically done using a CNC drill.

Step #4 Attach The Internal Components

Once the holes have been drilled, the internal components are then attached. This includes the vane, rotor, and shaft.

Step #5 Attach The Pump Cover

The final step is to attach the pump cover. This helps to protect the internal components from damage and debris.

Hydraulic vane pumps are essential components in a variety of industries and applications. Knowing how its manufacturing process works can help give you a better understanding of how this important piece of equipment works.

8. The Average Cost of Hydraulic Vane Pump

The average cost of a hydraulic vane pump can vary depending on the size, brand, and features of the pump. However, on average, the cost of a hydraulic vane pump is between $1,000 and $3,000.

This price range can be attributed to the various features and capabilities of each pump. For example, a high-pressure hydraulic vane pump will cost more than a standard model. Additionally, some brands may be more expensive than others.

When shopping for a hydraulic vane pump, it’s important to consider your needs and budget. Be sure to ask questions about the pump’s performance and warranty before making a purchase.

9. Where to Source for a Reliable Hydraulic Vane Pump Manufacturer

There are many places where you can source for a reliable hydraulic vane pump manufacturer. The most important thing is to ensure that the manufacturer you choose is reputable and has a good track record. Here are some places you can start your search:

Internet

The internet is a great place to start your search. You can find many manufacturers that sell hydraulic vane pumps online. Simply do a search for “hydraulic vane pump manufacturer” and you will be presented with a long list of potential suppliers.

Trde Shows

Another great place to find potential suppliers is at trade shows. This is a great opportunity to meet face-to-face with manufacturers and get a feel for their products and services. Attend as many trade shows as you can and make sure to collect business cards and brochures from all the manufacturers you meet.

Distributors

Another option is to contact distributors of hydraulic vane pumps. They usually have a good relationship with manufacturers and can help you find the right supplier for your needs.

Make sure to do your research before selecting a hydraulic vane pump manufacturer. This is a crucial decision that will impact the performance of your hydraulic system. Choose wisely! Additionally, you can contact us at Uphyd.

Uphyd is a reliable hydraulic vane pump manufacturer with a good track record. We have been in business for years and have supplied our products to many satisfied customers. Contact us today to learn more about our products and services!

10. 4 Buying Tips About Hydraulic Vane Pump

When looking to purchase a hydraulic vane pump, it is important to keep the following in mind:

#1 Hydraulic Fluid Viscosity

Hydraulic fluid viscosity is an important consideration when choosing a hydraulic vane pump. The higher the viscosity of the fluid, the greater the resistance to flow. Therefore, a pump with a higher capacity will be needed to move fluids with high viscosity. Additionally, the pump must be capable of handling the specific type of hydraulic fluid being used.

#2 Torque Ratings

The torque rating of a hydraulic vane pump is the amount of force that the pump can produce. Torque ratings will vary depending on the size and capacity of the pump. It is important to choose a pump with a torque rating that is appropriate for the application.

#3 Flow Rate

The flow rate of a hydraulic vane pump is the amount of fluid that the pump can move in a given period of time. Flow rates will vary depending on the size and capacity of the pump. It is important to choose a pump with a flow rate that is appropriate for the application.

#4 Max Operating Pressure

The maximum operating pressure of a hydraulic vane pump is the highest amount of pressure that the pump can withstand. Max operating pressure will vary depending on the size and capacity of the pump. It is important to choose a pump with a max operating pressure that is appropriate for the application.

By keeping these 4 factors in mind, you will be able to choose the best hydraulic vane pump for your business needs.

11. Conclusion

So there you have it, the ultimate guide to hydraulic vane pumps. We hope that this article was informative and helpful. If you have any further questions or need assistance in finding the right pump for your business needs, please do not hesitate to contact us at Uphyd. We would be happy to help!

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.