PRODUCT FEATURES

Hydraulic Power Pack Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

Hydraulic Power Pack Manufacturers: The Definitive Guide to Wholesalers

If you’re in the market for a hydraulic power pack, you may be wondering where to start your search. Hydraulic power packs are manufactured by a variety of companies, and it can be difficult to determine who is best suited to meet your needs.

In this guide, we’ll introduce you to the best hydraulic power pack manufacturers out there. We’ll also tell you about the different types of hydraulic power packs available and how to choose the right one for your business.

So, if you’re ready to learn more about hydraulic power packs, let’s get started!

Table of contents

1. What Is Hydraulic Power Pack?

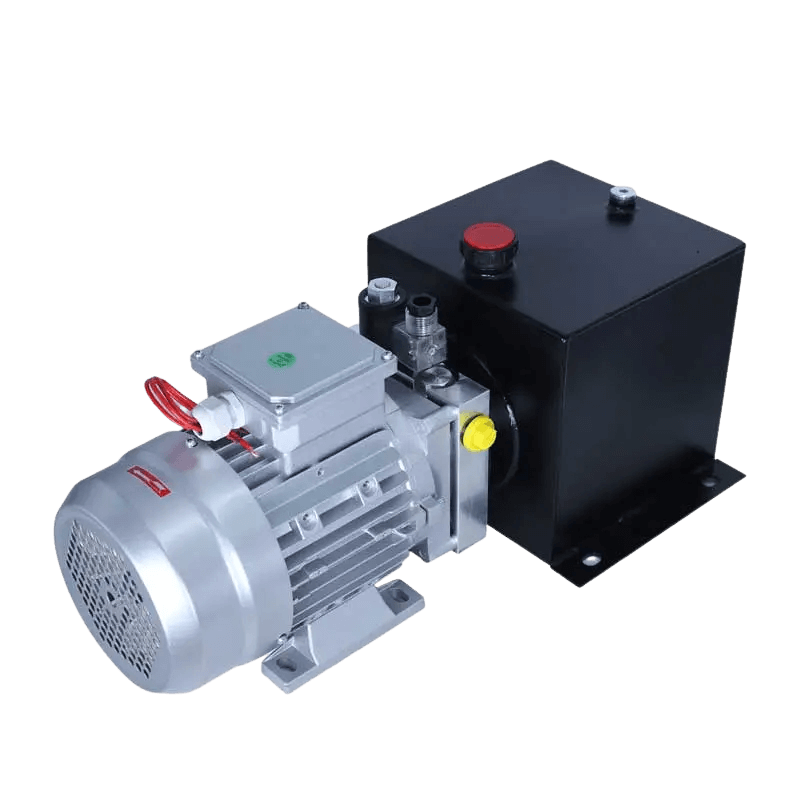

A hydraulic power pack is a self-contained unit that provides the necessary power to operate a hydraulic system. It consists of a drive motor, a hydraulic pump, and a hydraulic fluid tank that are all integrated into a single unit.

A hydraulic power pack works by using a drive motor to turn a hydraulic pump. The pump then pressurizes the hydraulic fluid, which is stored in the power pack’s tank. The pressurized fluid is then sent to the system components that need it, such as cylinders or motors.

The power pack is the heart of any hydraulic system. It is responsible for providing the necessary pressure and flow to operate the system components. Without a properly functioning power pack, a hydraulic system will not be able to function.

2. Key Features

There are a number of key features that make the hydraulic power pack an essential part of any hydraulic system. Here are just a few of them:

| Compact Size | One of the most important features of the hydraulic power pack is its compact size. The unit is designed to be small and lightweight, making it easy to install and operate. |

| High Efficiency | Another key feature of the hydraulic power pack is its high efficiency. The unit is able to generate a large amount of power while using very little energy, making it an ideal choice for applications where power efficiency is important. |

| Low Maintenance | The hydraulic power pack is also very low maintenance. The unit does not require frequent servicing or repairs, and it is designed to last for many years with minimal care. |

| Versatile | The hydraulic power pack is also very versatile. It can be used in a variety of applications, including automotive, aerospace, and construction. |

These are just a few of the key features that make the hydraulic power pack an essential part of any hydraulic system. If you are in need of a reliable and powerful hydraulic unit, the hydraulic power pack is a perfect choice.

3. Main Component and Their Function

There are several main components of a hydraulic power pack that works together to create the desired output. These components include:

Accumulators

The accumulator is one of the most important components of a hydraulic power pack. Its function is to store energy in the form of hydraulic fluid under pressure. This stored energy can then be used to power hydraulic devices when needed.

Motor Pumps

Motor pumps are used to generate hydraulic pressure. They work by using an electric motor to drive a hydraulic pump. The pump then pressurizes the hydraulic fluid, which is then stored in the accumulator.

Tanks

Tanks are used to store hydraulic fluid. They are usually made of steel or aluminum and can be either vertical or horizontal in orientation.

Filters

Filters are used to remove contaminants from the hydraulic fluid. This is important because contamination can cause damage to the hydraulic components.

Coolers and Heaters

Coolers and heaters are used to regulate the temperature of the hydraulic fluid. This is important because hydraulic fluid can degrade if it gets too hot or cold.

Power Unit Controllers

Power unit controllers are used to control the hydraulic power pack. They typically include power switches, displays, and monitoring features.

These are the main components of a hydraulic power pack and their respective functions. Understanding how these components work together is essential for troubleshooting and maintaining your hydraulic power pack.

4. 5 Industry Application

The hydraulic power pack is a versatile piece of equipment that can be used in a variety of industries. Some of the most common applications for hydraulic power packs include:

#1 Automotive

The hydraulic power pack is an essential piece of equipment in the automotive industry. It is used to power hydraulic brakes, hydraulic lifts, and other hydraulic systems in vehicles.

#2 Construction

The hydraulic power pack is also used extensively in the construction industry. It is used to power hydraulic excavators, hydraulic cranes, and other hydraulic equipment.

#3 Manufacturing

The hydraulic power pack is also used in the manufacturing industry. It is used to power hydraulic presses, hydraulic injection molding machines, and other hydraulic machinery.

#4 Mining

The hydraulic power pack is also used in the mining industry. It is used to power hydraulic shovels, hydraulic drills, and hydraulic crushers.

#5 Oil and Gas

The industrial hydraulic power unit is also used in the oil and gas industry. It is used to power hydraulic pumps, hydraulic valves, and hydraulic drilling rigs.

These are just a few of the many industries that use hydraulic power packs. Hydraulic power packs are versatile pieces of equipment that can be used in a variety of applications because of their unique ability to generate and transfer hydraulic power.

5. The Manufacturing Process

The manufacturing process of hydraulic power packs is not as simple as it might seem at first glance. In order to ensure that the finished product is of high quality and will be able to meet the needs of its users, a number of steps must be followed during the manufacturing process. Here is a look at the hydraulic power pack manufacturing process:

Step#1 Design and Development

The first step in the hydraulic power pack manufacturing process is the design and development phase. During this phase, the team of engineers responsible for creating the hydraulic power pack will work to create a product that meets the specific needs of their client.

This phase will involve a great deal of research and experimentation in order to create a prototype that can be used to test the feasibility of the design.

Step#2 Material Selection

Once the design of the hydraulic power pack has been finalized, the next step is to select the materials that will be used to create it. The hydraulic power pack will need to be made out of materials that are strong and durable enough to withstand the high pressures that will be exerted on it.

Step#3 Component Fabrication

After the materials have been selected, the next step is to begin fabricating the individual components that will make up the hydraulic power pack. This stage of the process requires a great deal of precision in order to ensure that all of the components will fit together properly.

Step#4 Assembly

The next step in the hydraulic power pack manufacturing process is assembly. During this phase, all of the individual components that have been created will be brought together and assembled into a single unit to create the hydraulic power pack.

Here’s a video of how to assemble the hydraulic power pack, check this video!

Step#5 Testing and Quality Control

The final step in the hydraulic power pack manufacturing process is testing and quality control. In order to ensure that the hydraulic power pack is of the highest possible quality, it will need to undergo a series of tests before it can be released onto the market.

These tests will assess the hydraulic power pack’s performance under a variety of conditions and help to identify any potential problems. After the hydraulic power pack has passed all of these tests, it will be ready to be sold to consumers.

In order to ensure that the hydraulic power pack is of the highest possible quality, it is important to follow all of the steps in the manufacturing process. By doing so, you can be sure that your hydraulic power pack will be able to withstand the high pressures it will be subjected to and provide years of reliable service.

6. The Average Cost of Hydraulic Power Pack

Generally speaking, the average cost of a hydraulic power pack will be between $300 and $1,000. However, the average cost of a hydraulic power pack will vary depending on the size, type, and brand of the hydraulic power pack.

Want to buy a hydraulic power pack China? Check out our website at Uphyd. We offer custom hydraulic power units at competitive prices. Our team of experts is available to help you find the perfect hydraulic power pack for your needs. Contact us today to learn more!

7. How To Work With Hydraulic Power Pack Manufacturer

When working with the manufacturer, there are a few things you should keep in mind in order to get the most out of your experience. Here are a few tips on how to work with a hydraulic power pack manufacturer:

Make Sure You Know What You Want

It is important that you have a clear idea of hydraulic power packs before contacting the manufacturer. This will make it easier for the 2 of you to communicate and come to an agreement.

Have A Budget In Mind

Hydraulic power packs can be expensive, so it is important to have a budget in mind before reaching out to the manufacturer. This will help to ensure that you do not overspend and that you get the hydraulic power pack that you need.

Be Clear About Your Needs

When contacting the hydraulic power pack manufacturer, be sure to let them know exactly what you need the hydraulic power pack for. This will help them to better understand your needs and provide you with the right product.

Get A Quote In Writing

When you have found a hydraulic power pack manufacturer that you are interested in working with, be sure to get a quote in writing before making any decisions. This will help to protect you in case of any unexpected costs.

These are just a few tips on how to work with a hydraulic power pack manufacturer. By following these tips, you can be sure that you will have a positive experience and that you will get the hydraulic power pack that is right for your needs.

8. 5 Tips When Sourcing for Manufacturer

When sourcing for a hydraulic power pack manufacturer, there are a few key factors you should keep in mind to ensure that you find the best possible partner for your needs. Here are some tips:

#1 Do Your Research

When it comes to hydraulic power packs, you can’t just go with the first manufacturer you find. It’s important to do your research and ask around to see who has the best reputation. Look for online reviews and testimonials from past clients to get an idea of what each manufacturer is like to work with.

#2 Consider Their Capabilities

Not all hydraulic power pack suppliers are created equal. Some specialize in certain types of products or have more experience than others. When you’re looking for a manufacturer, make sure to consider their capabilities to ensure they can meet your specific needs.

#3 Compare Prices

Of course, price is always a factor when it comes to hydraulic power packs. But, it’s important to remember that you get what you pay for. Don’t just choose the cheapest manufacturer you can find – make sure they offer a good value for the price.

#4 Ask for Samples

Before making your final decision, be sure to ask for samples from each hydraulic power pack manufacturer you’re considering. This will give you a chance to see the quality of their products firsthand and make sure they meet your standards.

#5 Check Their Credentials

Last but not least, always make sure to check the credentials of any hydraulic power unit manufacturers you’re thinking about working with. Check for things like ISO certification and industry accreditations to ensure they’re a reputable company.

These are just a few things to keep in mind when sourcing hydraulic power packs. By following these tips, you can be sure to find the best manufacturer for your needs.

Looking for a reputable hydraulic power pack manufacturer? Uphyd is a great choice. We have years of experience in the industry and can provide you with high-quality products at a great price. Contact us today to learn more.

9. 5 Buying Tips About Hydraulic Power Pack

When it comes to finding the right hydraulic power pack for your needs, there are a few things you’ll want to keep in mind to ensure you make the best purchase possible. Here are a few tips to help you buy a hydraulic power pack:

#1 Application

The first thing you need to consider is what hydraulic power pack will be used for. There are a variety of hydraulic power packs on the market, each designed for different applications. You need to make sure you get a hydraulic power pack that is designed for the specific application you need it for to ensure it will operate properly and efficiently.

#2 Flow Rate

The hydraulic power pack must have a flow rate that is appropriate for the application. Otherwise, it will not operate correctly. Hydraulic power packs come in a variety of flow rates, so it is important to choose one that is right for the application.

#3 Pressure Rating

When you’re in the market for a hydraulic power pack, one of the key specifications to look at is the pressure rating. This is usually displayed in pounds per square inch (PSI) or bar. The pressure rating will tell you how much force the hydraulic power pack can generate. Make sure to choose a hydraulic power pack with a pressure rating that’s appropriate for your needs.

#4 Port Sizes

Hydraulic power packs have ports of various sizes. The port size will determine the diameter of the hydraulic hose that can be used with the power pack. Make sure to choose a hydraulic power pack with port sizes that are compatible with the hydraulic hoses you plan to use.

#5 Cost

Of course, the cost is always a factor to consider when making any purchase. The hydraulic power pack can range in price from a few hundred dollars to several thousand dollars. It’s important to find a hydraulic power pack that fits your budget and meets your needs.

These are just a few tips to keep in mind when you’re in the market for a hydraulic power pack. By following these tips, you can be sure to find the right hydraulic power pack for your needs.

10. Conclusion

So, there you have it. The definitive guide to hydraulic power pack manufacturers and wholesalers. We hope you found this information helpful and that it gives you a good starting point for your search for the perfect supplier.

If you need any help sorting through this list or have any other questions, don’t hesitate to contact us at Uphyd. We would be happy to assist you in any way we can.

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.